فوائد العمل مع شركة تصنيع قطع غيار السيارات البلاستيكية ذات السمعة الطيبة

| اسم المنتج | أجزاء صب حقن البلاستيك OEM |

| اقتباس | وفقًا للرسم الخاص بك (الحجم / المادة / التكنولوجيا المطلوبة / إلخ) |

| اسم المنتج | أجزاء صب حقن البلاستيك OEM |

| اقتباس | وفقًا للرسم الخاص بك (الحجم / المادة / التكنولوجيا المطلوبة / إلخ) |

فوائد مكونات السيارات البلاستيكية: كيف يُحدث البلاستيك ثورة في صناعة السيارات تشهد صناعة السيارات ثورة، والبلاستيك في طليعة هذا التحول. أصبحت المكونات البلاستيكية ذات شعبية متزايدة في صناعة السيارات بسبب فوائدها العديدة. مكونات السيارة البلاستيكية أخف وزنا وأكثر متانة وأكثر فعالية من حيث التكلفة من المكونات المعدنية التقليدية. يُحدث هذا التحول نحو المكونات البلاستيكية ثورة…

The Benefits of Using Plastic Components Parts in Guangzhou Manufacturing Plastic components parts play a crucial role in the manufacturing industry, especially in a city like Guangzhou, known for its booming manufacturing sector. These parts are essential for creating a wide range of products, from electronics to automotive components. There are several benefits to using…

When discussing plastic mould companies and the steel used in plastic moulding, it’s essential to understand the critical role that both play in the manufacturing process. Here’s a detailed look into both aspects: Plastic Mould Companies Plastic mould companies specialize in designing, manufacturing, and maintaining moulds used in the injection moulding process. These companies provide…

Understanding the Importance of Plastic Part Tolerance Standards Understanding the Importance of Plastic Part Tolerance Standards In the world of manufacturing, precision and accuracy are crucial. Whether it’s in the automotive industry, electronics, or consumer goods, the quality of the final product depends on the precision of its individual components. One such component that plays…

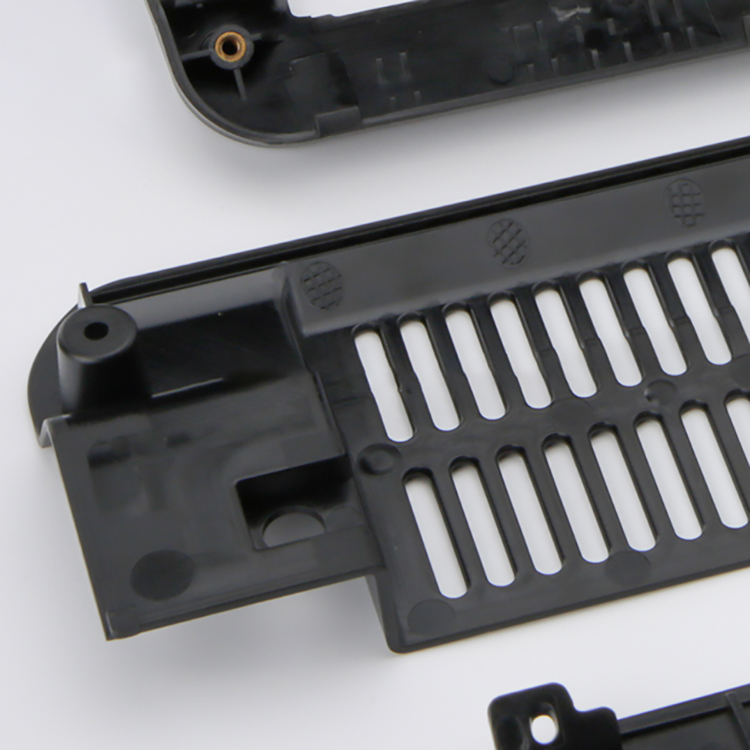

Benefits of Using Plastic Injection Parts in Manufacturing Plastic injection parts have become a staple in the manufacturing industry due to their numerous benefits. From cost-effectiveness to versatility, these parts offer a wide range of advantages that make them a popular choice for many manufacturers. One of the key benefits of using plastic injection parts…

The Impact of Plastic Particles on Marine Life Plastic particles have become a significant concern in recent years due to their detrimental impact on marine life. These tiny fragments, often invisible to the naked eye, are causing widespread damage to the delicate ecosystems that exist beneath the ocean’s surface. The consequences of plastic pollution are…