Los beneficios de utilizar componentes plásticos para muebles: exploración de las ventajas de durabilidad, rentabilidad y versatilidad

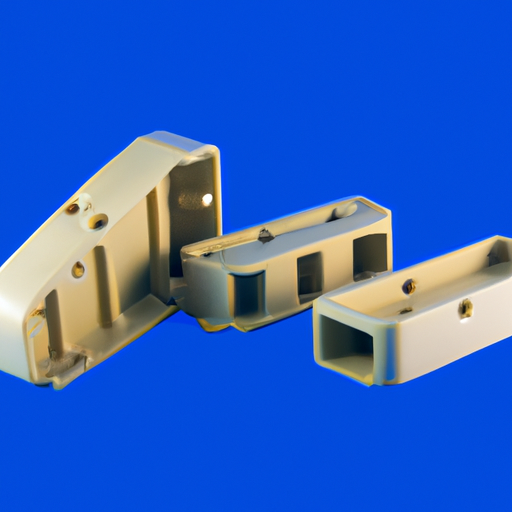

Los beneficios de utilizar piezas de plástico en la fabricación En lo que respecta a la fabricación, las piezas de plástico son cada vez más populares. Desde la automoción hasta la medicina, las piezas de plástico se utilizan en una variedad de industrias. Pero ¿por qué son tan populares las piezas de plástico? ¿Cuáles son…

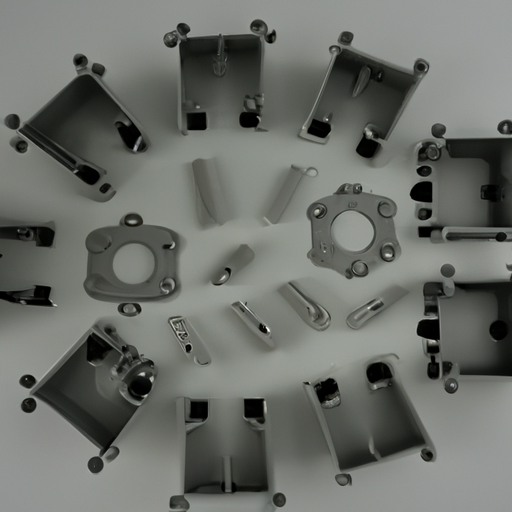

Certainly! In manufacturing and product development, “model” and “prototype” are terms often used to describe different stages and purposes of the development process. Model:A model typically refers to a representation of a product or system that may or may not function like the final product. Models are used primarily to visualize and test design concepts,…

Cómo preparar piezas de plástico de un automóvil para pintarlas: una guía paso a paso Pintar piezas de plástico para automóviles puede ser una excelente manera de darle a su automóvil un aspecto nuevo y fresco. Con la preparación adecuada, puedes lograr un acabado de apariencia profesional. Sigue esta guía paso a paso para preparar…

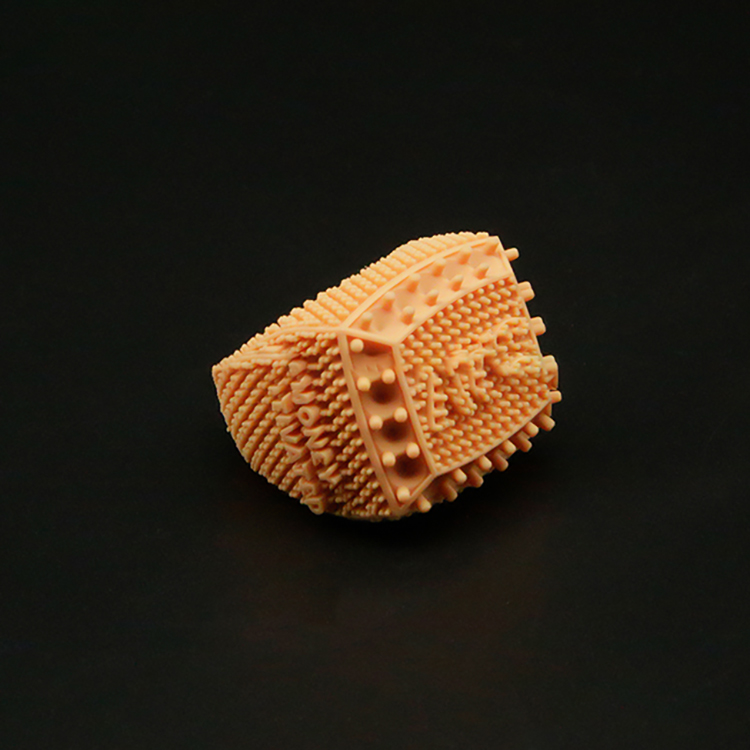

Introducción al molde de plástico de tres partes Un molde de plástico de tres partes es un tipo de molde utilizado en el proceso de moldeo por inyección de plástico. Está diseñado para crear piezas de plástico complejas que no se pueden producir fácilmente con un molde de dos partes. Este artículo proporcionará una introducción…

Las ventajas de las piezas moldeadas de plástico en los procesos de fabricación Las piezas de moldeo de plástico se han convertido en un componente integral en los procesos de fabricación de diversas industrias. Desde la automoción hasta la electrónica, estas piezas ofrecen numerosas ventajas que las convierten en la opción preferida de los fabricantes….

Consideraciones clave para un diseño eficaz de piezas de plástico El diseño de piezas de plástico es un aspecto crítico del desarrollo de productos, ya que afecta directamente la funcionalidad, durabilidad y calidad general del producto final. Ya sea que esté diseñando un componente pequeño o un conjunto complejo, hay varias consideraciones clave que se…