Table of Contents

Cara Memilih Suku Cadang Plastik yang Tepat untuk Ruangan Sejuk Anda

Manfaat Penggunaan Spare Part Plastik pada Konstruksi Ruangan Sejuk

Table of Contents

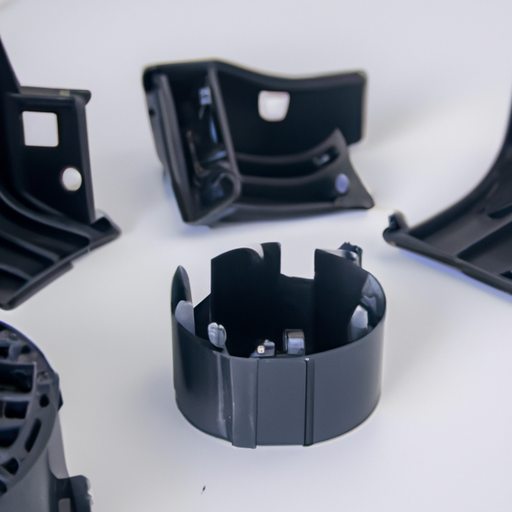

Producing ABS injection molded plastic parts for low-volume production involves several considerations and steps to ensure quality and cost-effectiveness. Here’s a structured approach: (1).Design Preparation: Start with detailed CAD designs optimized for injection molding. Ensure designs consider draft angles, wall thickness, and part geometry suitable for ABS.(2).Prototype Development: Create prototypes using rapid prototyping methods like…

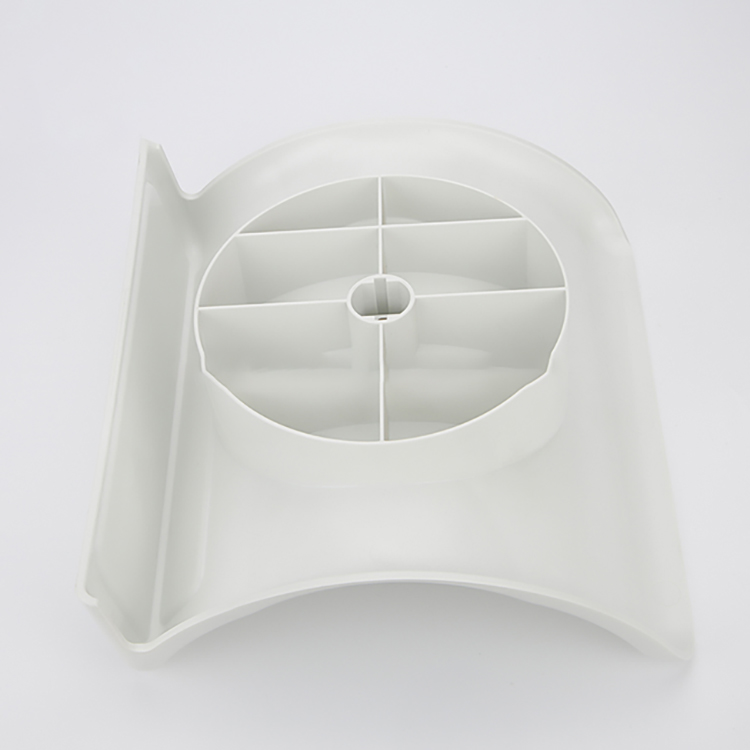

Techniques for Molding Thick Plastic Parts Techniques for Molding Thick Plastic Parts Molding thick plastic parts requires specific techniques to ensure the desired outcome. The process involves heating the plastic material until it becomes molten and then injecting it into a mold cavity. However, molding thick plastic parts presents unique challenges due to the increased…

The Importance of Plastic Communication Components in Modern Technology The Importance of Plastic Communication Components in Modern Technology Delivery PE bag + paper card/paper skin + export-grade carton / crate / Pallet Technology Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding In today’s fast-paced world, communication plays a…

ABS injection molding is commonly used to manufacture plastic parts for various applications, including car mount holders. ABS (Acrylonitrile Butadiene Styrene) is chosen for its strength, impact resistance, and affordability, making it suitable for products that require durability and a smooth finish.When producing ABS plastic parts for car mount holders through injection molding, manufacturers typically…

The Benefits of ABS PP PC PA66 Plastic Injection Parts in Manufacturing Plastic injection parts have become an integral part of the manufacturing industry. They are widely used in various sectors, including automotive, electronics, and consumer goods. Among the different types of plastic injection parts, ABS PP PC PA66 stands out as a popular choice….

Menjelajahi Manfaat Toleransi Ketat pada Komponen Injeksi Plastik Penggunaan toleransi ketat pada komponen injeksi plastik menjadi semakin populer di industri manufaktur. Toleransi ketat adalah ukuran seberapa dekat suatu bagian harus sesuai dengan spesifikasi desainnya. Toleransi yang ketat sering digunakan dalam produksi komponen injeksi plastik karena dapat memberikan sejumlah manfaat. Proses Produksi Pesanan-Bahan Baku- Pemeriksaan Kualitas…