Table of Contents

베르세파두 셀라탄 터미널의 편의성 탐색: 이용 가능한 서비스 및 편의시설 안내

Bersepadu Selatan 터미널이 말레이시아 대중교통을 어떻게 재정의하고 있는가

| 제조과정 | 주문-원자재-생산-품질검사-포장-출하 |

| 우리의 서비스 | OEM/ODM |

Table of Contents

| 제조과정 | 주문-원자재-생산-품질검사-포장-출하 |

| 우리의 서비스 | OEM/ODM |

자동차 플라스틱 부품의 HS코드 체계의 이해 HS 코드 시스템은 수출입 목적으로 제품을 분류하고 식별하는 데 사용되는 국제적으로 인정된 분류 시스템입니다. 세관원과 무역업자가 의사소통할 수 있는 공통 언어를 제공하여 무역을 원활하게 하는 데 도움이 되는 표준화된 시스템입니다. 자동차 산업에서 HS 코드 시스템은 플라스틱 부품을 포함한 다양한 구성 요소를 식별하고 분류하는 데 특히 중요합니다. 자동차 플라스틱 부품은…

오토바이 제조에 플라스틱 부품을 사용하는 이점 오토바이 제조에 플라스틱 부품을 사용하면 업계에 혁명이 일어나 생산 공정을 더욱 효율적이고 비용 효율적으로 만드는 다양한 이점을 제공합니다. 성능 향상부터 내구성 향상까지, 플라스틱 부품은 현대 오토바이 제조의 필수 구성 요소입니다. 오토바이 제조에 플라스틱 부품을 사용하는 가장 중요한 이점 중 하나는 성능 향상입니다. 플라스틱 부품은 가볍고 내구성이 뛰어나 고성능 오토바이에…

자동차 디자인에서 플라스틱 부품의 이점 탐구 자동차 산업은 지속적으로 발전하고 있으며, 현대 자동차 설계에서 플라스틱 부품이 점점 더 중요해지고 있습니다. 플라스틱 부품은 자동차 설계자에게 매력적인 옵션이 되는 다양한 이점을 제공합니다. 플라스틱 부품의 주요 장점 중 하나는 경량이라는 점입니다. 플라스틱 부품은 금속 부품보다 훨씬 가볍기 때문에 차량 전체 중량을 줄이고 연비를 향상시킬 수 있습니다. 이는 주행…

Pros and Cons of Using Plastic Partitions in Office Spaces Plastic partitions have become a popular choice for dividing office spaces in recent years. These partitions offer a cost-effective and versatile solution for creating separate work areas while still maintaining an open and collaborative environment. However, like any design choice, there are both pros and…

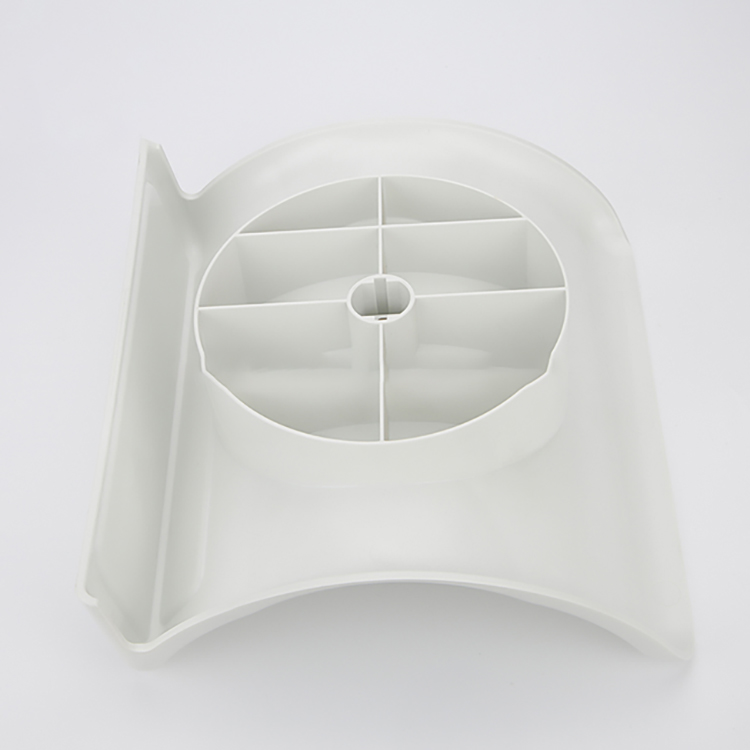

기구용 플라스틱 부품에 전위계를 사용하는 방법: 장점 및 용도 안내 제품명 OEM 플라스틱 사출성형 부품 도면형식 2D(PDF/CAD)와 3D(STP/STEP)

Producing ABS injection molded plastic parts for low-volume production involves several considerations and steps to ensure quality and cost-effectiveness. Here’s a structured approach: (1).Design Preparation: Start with detailed CAD designs optimized for injection molding. Ensure designs consider draft angles, wall thickness, and part geometry suitable for ABS.(2).Prototype Development: Create prototypes using rapid prototyping methods like…