Table of Contents

Soğuk Odanız için Doğru Plastik Yedek Parçaları Nasıl Seçersiniz?

Soğuk Oda Yapımında Plastik Yedek Parça Kullanmanın Faydaları

Table of Contents

Kendin Yap Halı Kurulumu: Halı Kaplama için Plastik Parçaları Kendi Başınıza Nasıl Takabilirsiniz Arabanıza halı kaplama için plastik parçaları kendiniz mi takmak istiyorsunuz? Öyleyse doğru yere geldiniz! Halı kaplama için plastik parçaların takılması göz korkutucu bir iş olabilir, ancak doğru aletlerle ve biraz sabırla bunu kendiniz yapabilirsiniz. Öncelikle gerekli araç ve malzemeleri toplamanız gerekecek. Halı…

Plastik Araba Bileşenlerinin Faydaları: Plastik Otomotiv Endüstrisinde Nasıl Devrim Yaratıyor Otomotiv endüstrisi bir devrim yaşıyor ve bu dönüşümün ön saflarında plastik yer alıyor. Plastik bileşenler, sayısız faydaları nedeniyle otomotiv endüstrisinde giderek daha popüler hale geliyor. Plastik araba bileşenleri, geleneksel metal bileşenlere göre daha hafif, daha dayanıklı ve daha uygun maliyetlidir. Plastik bileşenlere yönelik bu değişim,…

Benefits of Using Transparent Plastic Electronic Component Parts Transparent plastic electronic component parts are becoming increasingly popular in the electronics industry due to their numerous benefits. These parts are made from high-quality plastic materials that allow for easy visibility of the internal components of electronic devices. In this article, we will explore the advantages of…

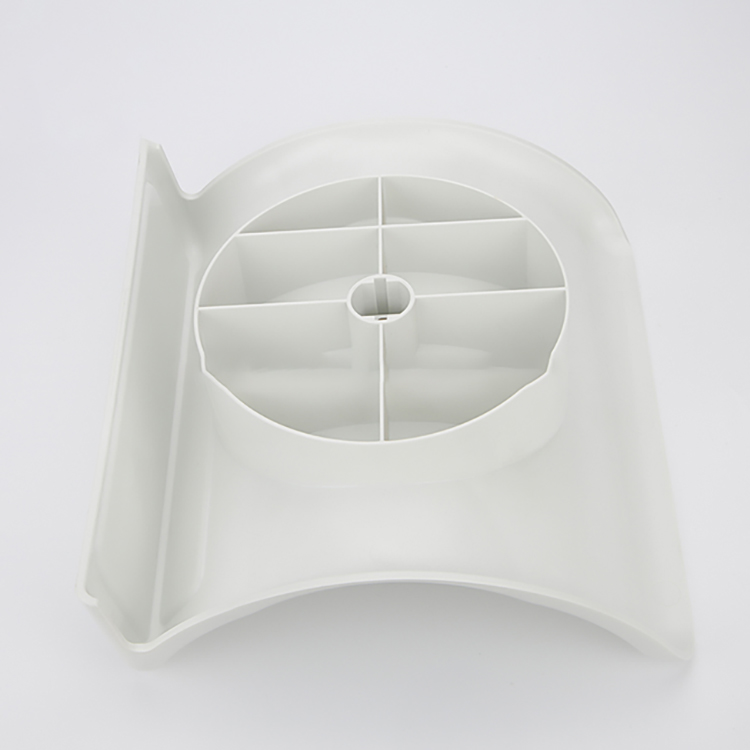

Producing ABS injection molded plastic parts for low-volume production involves several considerations and steps to ensure quality and cost-effectiveness. Here’s a structured approach: (1).Design Preparation: Start with detailed CAD designs optimized for injection molding. Ensure designs consider draft angles, wall thickness, and part geometry suitable for ABS.(2).Prototype Development: Create prototypes using rapid prototyping methods like…

Plastik Enjeksiyon Kalıp Bileşenlerinin Üretim İçin Avantajlarını Keşfetmek Plastik enjeksiyon kalıp bileşenleri, birçok avantajı nedeniyle imalat endüstrisinde giderek daha popüler hale geliyor. Bu bileşenler, tıbbi cihazlardan otomotiv parçalarına kadar çeşitli ürünler oluşturmak için kullanılır. Enjeksiyon kalıplama, istenilen şekli oluşturmak için erimiş plastiğin bir kalıba enjekte edilmesini içeren bir işlemdir. Bu süreç hızlı, verimli ve uygun…

To obtain affordable CNC aluminum parts, consider the following strategies: 1.Material Selection: Opt for more economical grades of aluminum such as 6061 aluminum alloy, which offers a good balance of strength, machinability, and cost-effectiveness compared to higher-grade alloys like 7075.2.Design Optimization: Simplify the design to reduce machining time and complexity. Complex geometries often require more…