Saygın Bir Plastik Otomobil Yedek Parça Üreticisiyle Çalışmanın Yararları

| Ürün Adı | OEM Plastik enjeksiyon kalıplama Parçaları |

| Alıntı | Çiziminize Göre (Boyut / Malzeme / Gerekli Teknoloji / Vb.) |

| Ürün Adı | OEM Plastik enjeksiyon kalıplama Parçaları |

| Alıntı | Çiziminize Göre (Boyut / Malzeme / Gerekli Teknoloji / Vb.) |

Plastik Enjeksiyon Kalıp Bileşenlerinin Üretim İçin Avantajlarını Keşfetmek Plastik enjeksiyon kalıp bileşenleri, birçok avantajı nedeniyle imalat endüstrisinde giderek daha popüler hale geliyor. Bu bileşenler, tıbbi cihazlardan otomotiv parçalarına kadar çeşitli ürünler oluşturmak için kullanılır. Enjeksiyon kalıplama, istenilen şekli oluşturmak için erimiş plastiğin bir kalıba enjekte edilmesini içeren bir işlemdir. Bu süreç hızlı, verimli ve uygun…

Overview of Current Developments Our collaboration has already yielded significant progress in the development of plastic parts and boxes. To recap: Objectives for the Next Phase As we transition to the next development phase, our objectives are to: Proposed Actions and Timeline To achieve these objectives, we propose the following plan: Collaboration and Communication We…

Techniques for Molding Thick Plastic Parts Techniques for Molding Thick Plastic Parts Molding thick plastic parts requires specific techniques to ensure the desired outcome. The process involves heating the plastic material until it becomes molten and then injecting it into a mold cavity. However, molding thick plastic parts presents unique challenges due to the increased…

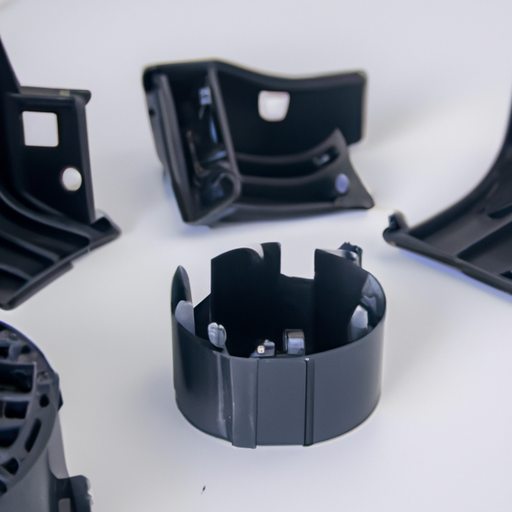

ABS (Acrylonitrile Butadiene Styrene) injection molding is commonly used for producing plastic parts, including car mount holders. Here are some key points regarding ABS injection molded parts for car mount holders: 1.Material Characteristics: 2.Strength: ABS offers good strength and rigidity, making it suitable for parts that need to withstand mechanical stresses, such as those in…

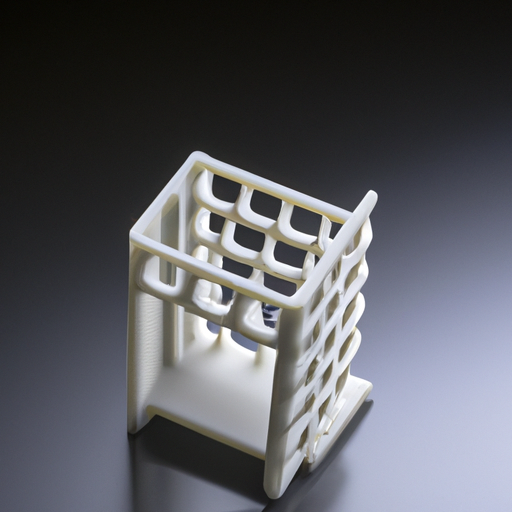

Low-volume rapid prototype manufacturing with rapid tooling refers to the process of quickly creating tools or molds to produce a small quantity of prototypes or parts. Here’s a detailed explanation of each component: 1.Low-Volume Manufacturing: This refers to producing a limited quantity of parts, typically ranging from a few units to a few thousand, often…

It sounds like you’re interested in manufacturing custom plastic parts with a small minimum production requirement. Here’s a breakdown of how this typically works:Custom Plastic Parts Manufacturing: 1.Design Phase: 2.CAD Design: Your custom plastic part design starts with a Computer-Aided Design (CAD) file. This file defines the dimensions, features, and specifications of the part.3.Prototype: Before…