OEM ishlab chiqarishda yirik plastik qismlarning ahamiyati

OEM ishlab chiqarishda yirik plastik qismlarning ahamiyati

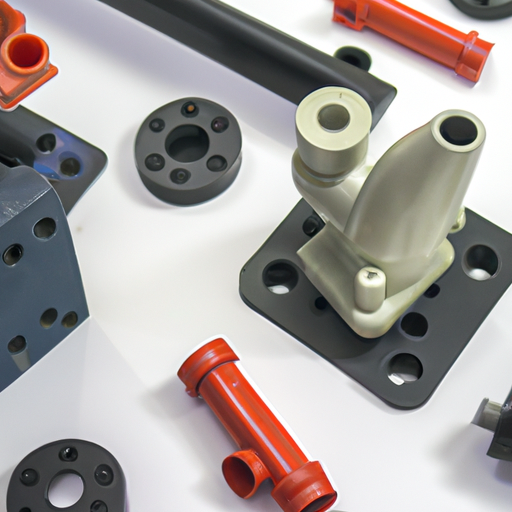

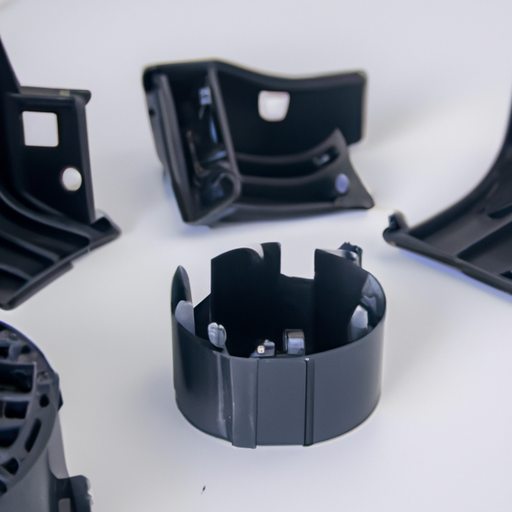

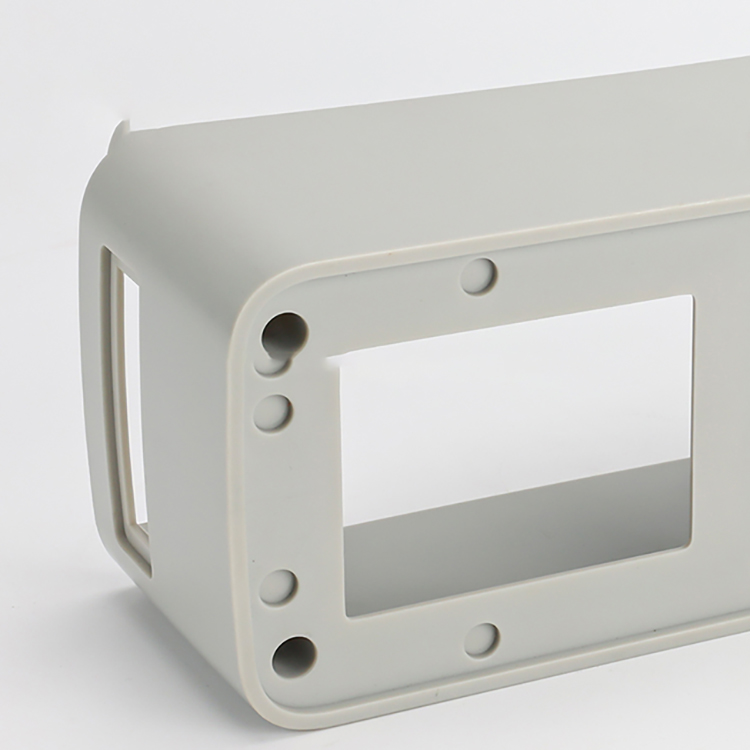

Asl uskunalar ishlab chiqarish (OEM) dunyosida katta plastik qismlar hal qiluvchi rol o’ynaydi. Ushbu qismlar avtomobilsozlik, aerokosmik, elektronika va iste’mol tovarlari kabi ko’plab sohalarda muhim komponentlardir. Ularning ahamiyati chidamlilik, ko’p qirrali va iqtisodiy samaradorlikni ta’minlash qobiliyatidadir.

| Ishlab chiqarish jarayoni | Buyurtmalar-xom ashyo-ishlab chiqarish-sifat nazorati-qadoqlash-jo’natish |

| Bizning xizmatlar | OEM/ODM |

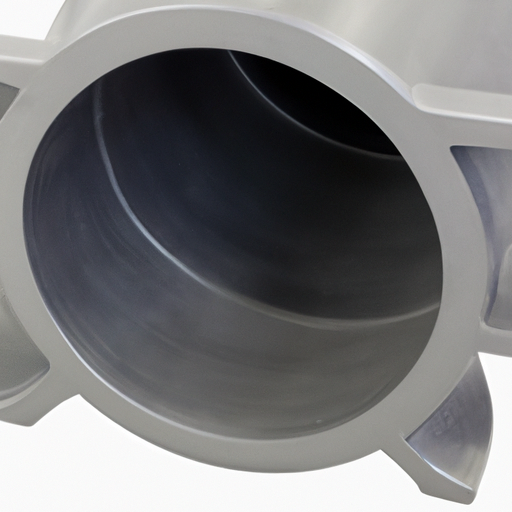

Katta plastik qismlar ishlab chiqarish samaradorligi nuqtai nazaridan ham afzalliklarga ega. Plastik qismlarni ishlab chiqarishda qo’llaniladigan eng keng tarqalgan usul bo’lgan plastik qarshi kalıplama minimal chiqindilar bilan yuqori hajmli ishlab chiqarish imkonini beradi. Bu jarayon eritilgan plastmassani qolipga quyishni o’z ichiga oladi, so’ngra kerakli shaklga aylanadi. Katta hajmdagi qismlarni tez va izchil ishlab chiqarish qobiliyati plastik inyeksion kalıplamani tejamkor va vaqtni tejaydigan ishlab chiqarish texnikasiga aylantiradi. Bu samaradorlik, ayniqsa, qat’iy muddatlar va yuqori talabni qondirishi kerak bo’lgan OEM kompaniyalari uchun foydalidir.

Bundan tashqari, katta plastik qismlar OEM ishlab chiqarishda barqarorlikka ijobiy ta’sir ko’rsatadi. Plastmassa qayta ishlanadigan materialdir va ko’plab OEM kompaniyalari qayta ishlangan plastmassani ishlab chiqarish jarayonlariga tobora ko’proq kiritmoqda. Qayta ishlangan plastmassadan foydalangan holda, bu kompaniyalar toza materiallarga bo’lgan ishonchni kamaytiradi va tabiiy resurslarni saqlashga hissa qo’shadi. Bundan tashqari, plastik qismlarning ishlash muddati oxirida oson qismlarga ajratish va qayta ishlash uchun mo’ljallangan bo’lishi mumkin, bu esa ularning atrof-muhitga ta’sirini yanada kamaytiradi.

Xulosa qilib aytganda, katta plastik qismlar chidamliligi, ko’p qirraliligi va iqtisodiy samaradorligi tufayli OEM ishlab chiqarishda muhim rol o’ynaydi. , ishlab chiqarish samaradorligi va barqarorligi. Ushbu qismlar turli sohalar uchun zarur kuch va chidamlilikni ta’minlaydi, shu bilan birga dizayn va moslashtirishda moslashuvchanlikni taklif qiladi. Ularning arzonligi va engilligi xarajatlarni tejashga va yoqilg’i samaradorligini oshirishga yordam beradi. Bundan tashqari, plastik qismlar minimal chiqindilar bilan yuqori hajmlarda ishlab chiqarilishi mumkin, bu ularni OEM kompaniyalari uchun samarali tanlov qiladi. Va nihoyat, ularning qayta ishlanishi va oson demontaj qilish potentsiali yanada barqaror ishlab chiqarish jarayoniga yordam beradi. Umuman olganda, katta plastik qismlar OEM ishlab chiqarish dunyosida ajralmas komponent hisoblanadi.

Large plastic parts also offer advantages in terms of production efficiency. Plastic injection molding, the most common method used for manufacturing plastic parts, allows for high-volume production with minimal waste. This process involves injecting molten plastic into a mold, which then solidifies into the desired shape. The ability to produce large quantities of parts quickly and consistently makes plastic injection molding a cost-effective and time-efficient manufacturing technique. This efficiency is particularly beneficial for OEM companies that need to meet tight deadlines and high demand.

Furthermore, large plastic parts have a positive impact on sustainability in OEM manufacturing. Plastic is a recyclable material, and many OEM companies are increasingly incorporating recycled plastic into their production processes. By using recycled plastic, these companies reduce their reliance on virgin materials and contribute to the conservation of natural resources. Additionally, plastic parts can be designed for easy disassembly and recycling at the end of their lifecycle, further minimizing their environmental impact.

In conclusion, large plastic parts play a vital role in OEM manufacturing due to their durability, versatility, cost-effectiveness, production efficiency, and sustainability. These parts provide the necessary strength and resilience for various industries, while also offering flexibility in design and customization. Their affordability and lightweight nature contribute to cost savings and improved fuel efficiency. Moreover, plastic parts can be produced in high volumes with minimal waste, making them an efficient choice for OEM companies. Lastly, their recyclability and potential for easy disassembly contribute to a more sustainable manufacturing process. Overall, large plastic parts are an indispensable component in the world of OEM manufacturing.