LPM plastik mototsikl qismlarini ishlatishning afzalliklari

LPM plastik mototsikl qismlari: ulardan foydalanishning afzalliklari

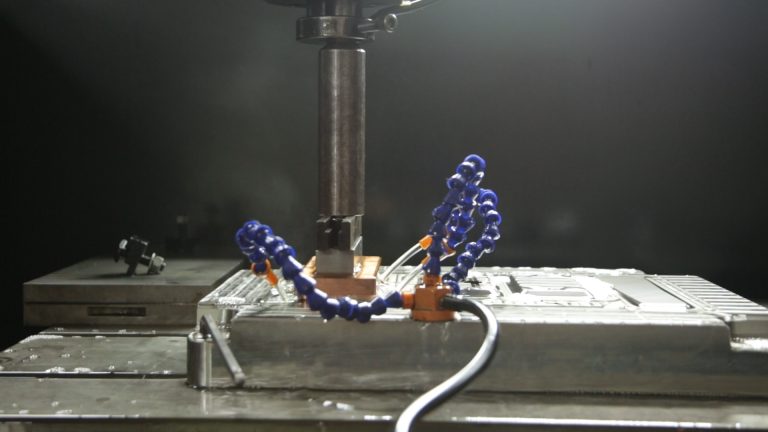

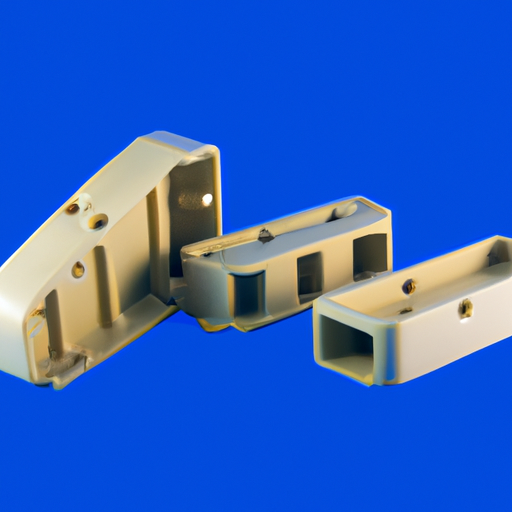

Mototsikl qismlari haqida gap ketganda, chidamlilik va unumdorlik katta ahamiyatga ega. Shuning uchun ko’plab chavandozlar LPM plastik mototsikl qismlariga murojaat qilmoqdalar. LPM yoki Liquid Plastic Molding – bu mototsikllar uchun yuqori sifatli plastik qismlarni ishlab chiqaradigan ishlab chiqarish jarayoni. Ushbu maqolada biz LPM plastik mototsikl qismlarini ishlatishning afzalliklarini va nima uchun ular chavandozlar orasida tobora ommalashib borayotganini ko’rib chiqamiz.

LPM plastik mototsikl qismlarining asosiy afzalliklaridan biri ularning engilligidir. An’anaviy metall qismlarga nisbatan, LPM plastik qismlari sezilarli darajada engilroq, bu esa mototsiklning umumiy ishlashiga ijobiy ta’sir ko’rsatishi mumkin. Kamaytirilgan og’irlik manevrni yaxshilash va yoqilg’i samaradorligini oshirish imkonini beradi, bu esa tezlik va samaradorlikni qadrlaydigan chavandozlar uchun jozibador tanlovdir.

Mahsulot nomi

| OEM Plastik qarshi kalıplama qismlari | Texnologiya |

| Ko’piklash / Oddiy quyish / Strukturaviy ko’pikli kalıplama / Ortiqcha qoliplash / Gaz yordamida quyish | Bizning xizmatlar |

| OEM/ODM | Bundan tashqari, LPM plastik mototsikl qismlari mukammal dizayn moslashuvchanligini ta’minlaydi. Ishlab chiqarish jarayoni murakkab va murakkab shakllarni yaratishga imkon beradi, bu esa dizaynerlarga nafaqat funktsional, balki estetik jihatdan ham yoqimli qismlarni yaratish erkinligini beradi. Dizayndagi bu moslashuvchanlik moslashtirish uchun imkoniyatlar dunyosini ochib beradi, bu esa chavandozlarga o’zlarining noyob uslublari va afzalliklarini aks ettirish uchun mototsikllarini shaxsiylashtirishga imkon beradi.

Xarajat nuqtai nazaridan, LPM plastik mototsikl qismlari odatda metall hamkasblariga qaraganda ancha arzon. LPM plastik qismlarini ishlab chiqarish jarayoni odatda arzonroq bo’lib, ishlab chiqarish xarajatlarini kamaytiradi. Bu iqtisodiy samaradorlik LPM plastik qismlarini mototsikl komponentlarini yangilash yoki almashtirishni istaydigan chavandozlar uchun mos variantga aylantiradi. Nihoyat, LPM plastik mototsikl qismlari atrof-muhit uchun xavfsizdir. Ishlab chiqarish jarayoni an’anaviy metall ishlab chiqarish usullari bilan solishtirganda minimal chiqindilarni ishlab chiqaradi va kamroq energiya sarflaydi. Bundan tashqari, plastik qismlar qayta ishlanishi mumkin, bu esa atrof-muhitga ta’sirini yanada kamaytiradi. LPM plastik qismlarini tanlash orqali chavandozlar yanada yashil va barqaror kelajakka hissa qo’shishlari mumkin. Xulosa qilib aytganda, LPM plastik mototsikl qismlari ularni chavandozlar orasida mashhur tanlovga aylantiradigan ko’plab afzalliklarni taqdim etadi. LPM plastmassa qismlari engil va bardoshli tabiatidan korroziyaga chidamliligi va dizayn moslashuvchanligigacha mototsikllarning umumiy ishlashi va estetikasini yaxshilaydigan qator afzalliklarni beradi. Bundan tashqari, ularning arzonligi va ekologik tozaligi ularni sifat va barqarorlikni qadrlaydigan chavandozlar uchun jozibali variantga aylantiradi. Bu barcha afzalliklari bilan, LPM plastik mototsikl qismlari mototsikl sanoatida mashhurlikka erishayotgani ajablanarli emas. |

Furthermore, LPM plastic motorcycle parts offer excellent design flexibility. The manufacturing process allows for intricate and complex shapes to be created, giving designers the freedom to create parts that are not only functional but also aesthetically pleasing. This flexibility in design opens up a world of possibilities for customization, allowing riders to personalize their motorcycles to reflect their unique style and preferences.

In terms of cost, LPM plastic motorcycle parts are often more affordable than their metal counterparts. The manufacturing process for LPM plastic parts is generally less expensive, resulting in lower production costs. This cost-effectiveness makes LPM plastic parts a viable option for riders who are looking to upgrade or replace their motorcycle components without breaking the bank.

Lastly, LPM plastic motorcycle parts are environmentally friendly. The manufacturing process produces minimal waste and consumes less energy compared to traditional metal manufacturing methods. Additionally, plastic parts can be recycled, reducing the environmental impact even further. By choosing LPM plastic parts, riders can contribute to a greener and more sustainable future.

In conclusion, LPM plastic motorcycle parts offer numerous advantages that make them a popular choice among riders. From their lightweight and durable nature to their resistance to corrosion and design flexibility, LPM plastic parts provide a range of benefits that enhance the overall performance and aesthetics of motorcycles. Moreover, their affordability and environmental friendliness make them an attractive option for riders who value both quality and sustainability. With all these advantages, it’s no wonder that LPM plastic motorcycle parts are gaining popularity in the motorcycle industry.