L’importance des grandes pièces en plastique dans la fabrication OEM

Processus de production

| Commandes-Matières Premières- Production-Contrôle Qualité -Emballage-Expédition | Nos prestations |

| OEM/ODM | Les grandes pièces en plastique offrent également des avantages en termes d’efficacité de production. Le moulage par injection de plastique, la méthode la plus couramment utilisée pour fabriquer des pièces en plastique, permet une production en grand volume avec un minimum de déchets. Ce processus consiste à injecter du plastique fondu dans un moule, qui se solidifie ensuite pour prendre la forme souhaitée. La capacité de produire de grandes quantités de pièces de manière rapide et cohérente fait du moulage par injection plastique une technique de fabrication rentable et rapide. Cette efficacité est particulièrement bénéfique pour les entreprises OEM qui doivent respecter des délais serrés et une forte demande.

De plus, les grandes pièces en plastique ont un impact positif sur la durabilité dans la fabrication OEM. Le plastique est un matériau recyclable et de nombreuses entreprises OEM intègrent de plus en plus de plastique recyclé dans leurs processus de production. En utilisant du plastique recyclé, ces entreprises réduisent leur dépendance à l’égard de matériaux vierges et contribuent à la conservation des ressources naturelles. De plus, les pièces en plastique peuvent être conçues pour être facilement démontées et recyclées à la fin de leur cycle de vie, minimisant ainsi davantage leur impact environnemental. En conclusion, les grandes pièces en plastique jouent un rôle essentiel dans la fabrication OEM en raison de leur durabilité, de leur polyvalence et de leur rentabilité. , l’efficacité de la production et la durabilité. Ces pièces offrent la résistance et la résilience nécessaires à diverses industries, tout en offrant également une flexibilité de conception et de personnalisation. Leur prix abordable et leur légèreté contribuent à des économies de coûts et à une meilleure efficacité énergétique. De plus, les pièces en plastique peuvent être produites en grande quantité avec un minimum de déchets, ce qui en fait un choix efficace pour les entreprises OEM. Enfin, leur recyclabilité et leur potentiel de démontage facile contribuent à un processus de fabrication plus durable. Dans l’ensemble, les grandes pièces en plastique sont un composant indispensable dans le monde de la fabrication OEM. |

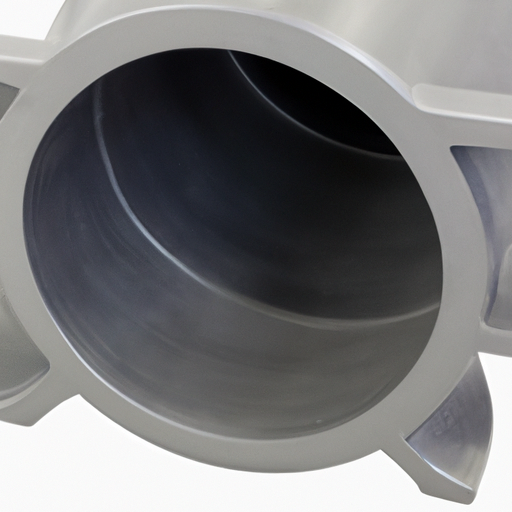

One of the primary reasons why large plastic parts are highly valued in OEM manufacturing is their durability. Unlike other materials, such as metal or glass, plastic is known for its resilience and ability to withstand harsh conditions. This makes it an ideal choice for manufacturing parts that need to endure extreme temperatures, pressure, or impact. For example, in the automotive industry, large plastic parts are used in the production of bumpers, fenders, and interior components, which need to withstand collisions and provide protection to passengers.

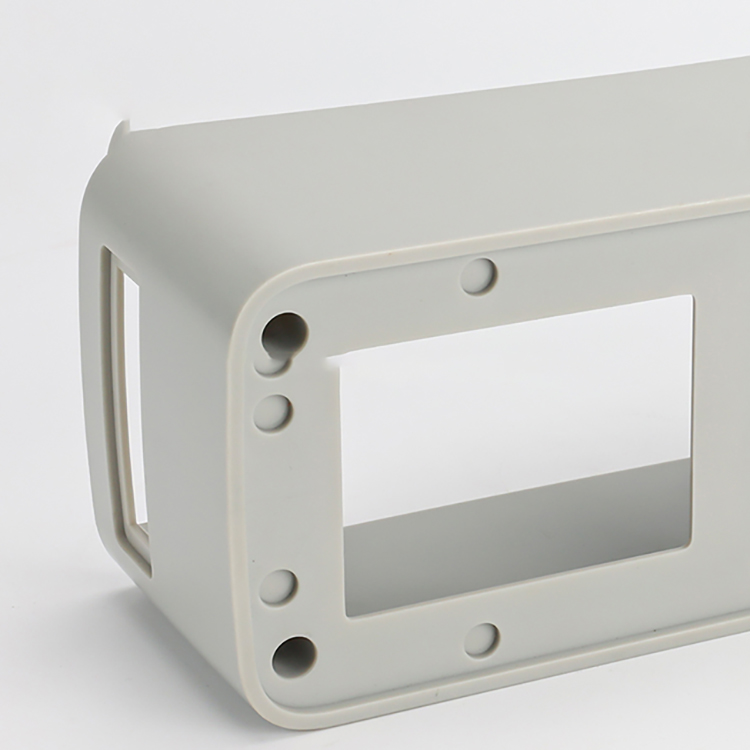

Versatility is another key advantage of large plastic parts in OEM manufacturing. Plastic can be molded into various shapes and sizes, allowing manufacturers to create complex designs and intricate details. This flexibility enables OEM companies to meet the specific requirements of their clients and produce customized parts that fit perfectly into their products. Moreover, plastic parts can be easily modified or redesigned, making them adaptable to changes in design or functionality. This versatility is particularly valuable in industries where innovation and product differentiation are crucial for success.

Cost-effectiveness is a significant factor that contributes to the importance of large plastic parts in OEM manufacturing. Plastic is a relatively inexpensive material compared to alternatives like metal or glass. This affordability makes it an attractive choice for OEM companies looking to reduce production costs without compromising on quality. Additionally, plastic parts are lightweight, which can lead to savings in transportation and assembly. The lower weight also contributes to fuel efficiency in industries like automotive and aerospace, where every ounce matters.

Large plastic parts also offer advantages in terms of production efficiency. Plastic injection molding, the most common method used for manufacturing plastic parts, allows for high-volume production with minimal waste. This process involves injecting molten plastic into a mold, which then solidifies into the desired shape. The ability to produce large quantities of parts quickly and consistently makes plastic injection molding a cost-effective and time-efficient manufacturing technique. This efficiency is particularly beneficial for OEM companies that need to meet tight deadlines and high demand.

Furthermore, large plastic parts have a positive impact on sustainability in OEM manufacturing. Plastic is a recyclable material, and many OEM companies are increasingly incorporating recycled plastic into their production processes. By using recycled plastic, these companies reduce their reliance on virgin materials and contribute to the conservation of natural resources. Additionally, plastic parts can be designed for easy disassembly and recycling at the end of their lifecycle, further minimizing their environmental impact.

In conclusion, large plastic parts play a vital role in OEM manufacturing due to their durability, versatility, cost-effectiveness, production efficiency, and sustainability. These parts provide the necessary strength and resilience for various industries, while also offering flexibility in design and customization. Their affordability and lightweight nature contribute to cost savings and improved fuel efficiency. Moreover, plastic parts can be produced in high volumes with minimal waste, making them an efficient choice for OEM companies. Lastly, their recyclability and potential for easy disassembly contribute to a more sustainable manufacturing process. Overall, large plastic parts are an indispensable component in the world of OEM manufacturing.