Les avantages de travailler avec un fabricant réputé de pièces détachées automobiles en plastique

| Nom du produit | Pièces de moulage par injection plastique OEM |

| Citation | Selon votre dessin (taille/matériau/technologie requise/Etc.) |

| Nom du produit | Pièces de moulage par injection plastique OEM |

| Citation | Selon votre dessin (taille/matériau/technologie requise/Etc.) |

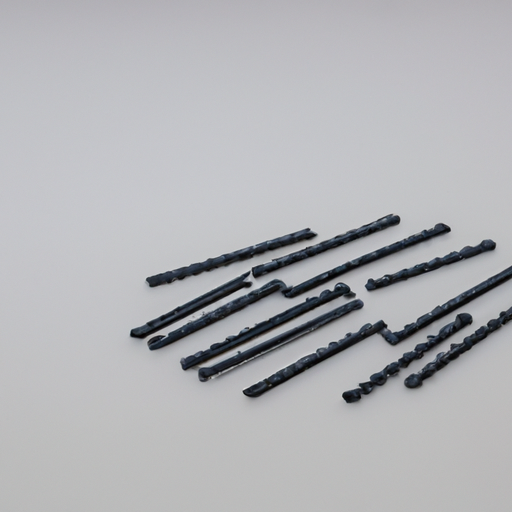

CNC Aluminum Parts and Aluminum CNC Milling Parts: An In-Depth Exploration Introduction 1. Characteristics of Aluminum and CNC Machining 1.1 Aluminum Material Properties Aluminum is renowned for its combination of properties that make it ideal for various applications: Lightweight: With a density approximately one-third that of steel, aluminum is ideal for applications where weight reduction…

Les avantages de l’utilisation de pièces en plastique pour les applications automobiles L’un des principaux avantages de l’utilisation de pièces en plastique pour les applications automobiles est leur légèreté. Les pièces en plastique sont beaucoup plus légères que les pièces en métal, ce qui peut réduire le poids total du véhicule et améliorer le rendement…

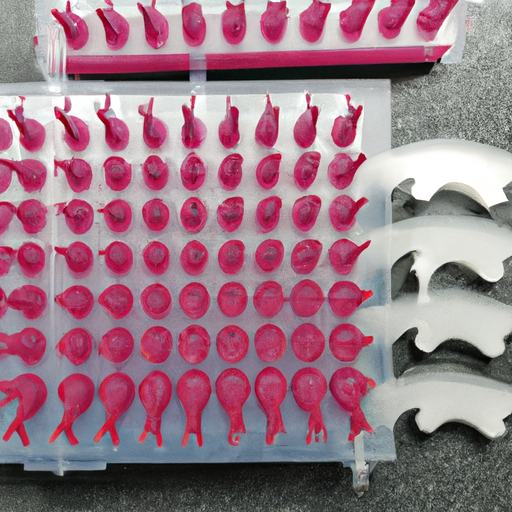

Les avantages de l’usinage CNC pour les pièces de composants PI en plastique L’usinage CNC a révolutionné l’industrie manufacturière, offrant une production précise et efficace de divers composants et pièces. Lorsqu’il s’agit de pièces de composants PI en plastique, l’usinage CNC s’avère être un excellent choix, offrant de nombreux avantages qui en font la méthode…

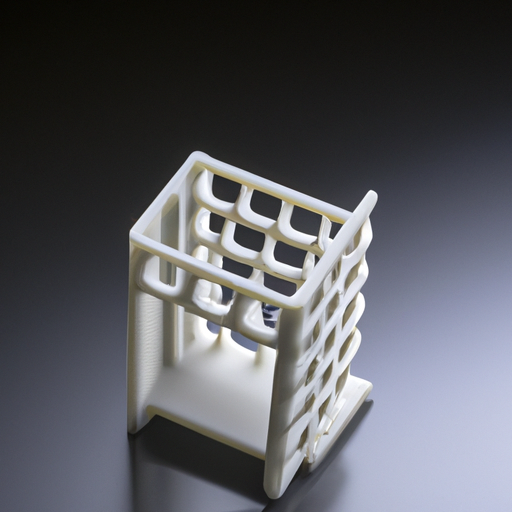

Les avantages de l’utilisation directe de pièces en plastique dans les processus de fabrication Livraison Sac PE + carte papier/peau de papier + carton/caisse/palette de qualité exportation Technologie Mousse / Injection ordinaire / Moulage de mousse structurelle / Surmoulage / Moulage par injection assisté par gaz En plus des économies de coûts, d’un contrôle accru…

The Benefits of Using ABS Building Products for Construction Projects ABS Building Products Pte Ltd is a leading provider of construction materials that are widely used in various construction projects. With a wide range of products available, ABS Building Products has become a trusted name in the industry. In this article, we will explore the…

Les avantages de l’utilisation de peignes antistatiques en plastique personnalisés pour la résistance à la chaleur Peignes antistatiques en plastique pour raie sur mesure pour la résistance à la chaleur Quand il s’agit de coiffer nos cheveux, nous comptons souvent sur divers outils et produits pour obtenir le look souhaité. L’un de ces outils qui…