Les avantages de l’utilisation de composants en plastique pour les meubles : explorer les avantages de la durabilité, de la rentabilité et de la polyvalence

Understanding the Importance of Adhesion Mechanisms in Automotive Plastic Parts Adhesion mechanisms play a crucial role in the performance and durability of automotive plastic parts. These mechanisms are responsible for ensuring that various components of a vehicle remain securely bonded together, even under harsh conditions such as extreme temperatures, vibrations, and exposure to chemicals. Understanding…

Explorer les avantages des tolérances strictes dans les pièces d’injection plastique Processus de production Commandes-Matières Premières- Production-Contrôle Qualité -Emballage-Expédition Nos prestations OEM/ODM Comment obtenir une qualité constante des pièces d’injection plastique grâce au contrôle des tolérances Le contrôle des tolérances est un facteur important pour obtenir une qualité constante des pièces injectées en plastique. C’est…

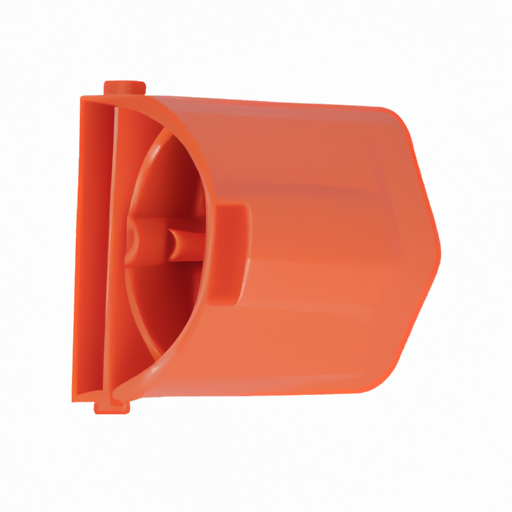

Comprendre les composants clés des moules d’injection plastique Les moules d’injection plastique sont des outils essentiels dans l’industrie manufacturière. Ils sont utilisés pour fabriquer une large gamme de produits en plastique, allant des simples articles ménagers aux pièces automobiles complexes. Comprendre les composants clés des moules d’injection plastique est crucial pour toute personne impliquée dans…

L’impact de l’évier à pièces en plastique sur l’environnement Processus de production Commandes-Matières Premières- Production-Contrôle Qualité -Emballage-Expédition Nos prestations OEM/ODM Les éviers en plastique ne sont pas seulement un problème dans les environnements marins mais également dans les plans d’eau douce. Les rivières et les lacs sont souvent la destination finale des déchets plastiques, et…

Understanding the Importance of Plastic Part Tolerance Standards Understanding the Importance of Plastic Part Tolerance Standards In the world of manufacturing, precision and accuracy are crucial. Whether it’s in the automotive industry, electronics, or consumer goods, the quality of the final product depends on the precision of its individual components. One such component that plays…

Comment minimiser le gauchissement des pièces en plastique : conseils et techniques pour les concepteurs et les fabricants Heureusement, il existe quelques astuces et techniques que vous pouvez utiliser pour minimiser la déformation des pièces en plastique. Dans cet article de blog, nous discuterons de certains des moyens les plus efficaces de réduire le gauchissement et…