Menjelajahi Berbagai Jenis Komponen Mesin Cetak Injeksi Plastik dan Kegunaannya

Kelebihan Komponen Plastik Cetakan Injeksi dalam Proses Manufaktur Komponen plastik cetakan injeksi telah menjadi bagian integral dari industri manufaktur. Dengan berbagai keunggulannya, mereka telah merevolusi cara pembuatan produk. Pada artikel ini, kita akan mengeksplorasi keunggulan komponen plastik cetakan injeksi dalam proses manufaktur. Salah satu keunggulan utama komponen plastik cetakan injeksi adalah efektivitas biayanya. Dibandingkan dengan…

“Plastic production parts” and “plastic parts” generally refer to components or products that are manufactured using plastic materials. Here’s an overview: 1.Definition: Plastic parts are items made from various types of plastic materials through processes such as injection molding, extrusion, blow molding, or thermoforming. These parts can vary widely in size, shape, and complexity.2.Types: Plastic…

Menjelajahi Manfaat Komponen Cetakan Injeksi Plastik untuk Manufaktur Komponen cetakan injeksi plastik menjadi semakin populer di industri manufaktur karena banyak manfaatnya. Komponen-komponen ini digunakan untuk membuat berbagai produk, mulai dari peralatan medis hingga suku cadang otomotif. Cetakan injeksi adalah proses yang melibatkan penyuntikan plastik cair ke dalam cetakan untuk menciptakan bentuk yang diinginkan. Proses ini…

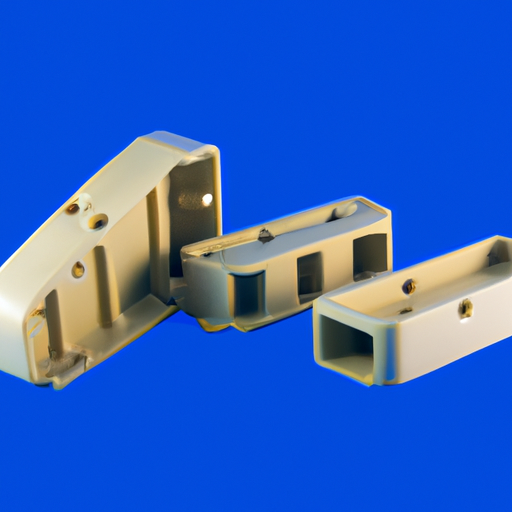

Pengenalan Cetakan Plastik Tiga Bagian Cetakan plastik tiga bagian adalah jenis cetakan yang digunakan dalam proses pencetakan injeksi plastik. Ini dirancang untuk membuat komponen plastik kompleks yang tidak dapat diproduksi dengan mudah dengan cetakan dua bagian. Artikel ini akan memberikan pengenalan tentang cetakan plastik tiga bagian, menjelaskan tujuan, konstruksi, dan kelebihannya. Pertama, mari kita bahas…

If you’re looking to create a plastic prototype of a functional component, especially for a product or a part that includes a functional aspect such as electronics integration, moving parts, or specific material properties, here are the general steps and considerations involved:Steps to Develop a Plastic Prototype for a Functional Component: 1.Conceptualization and Design: 2.Define…

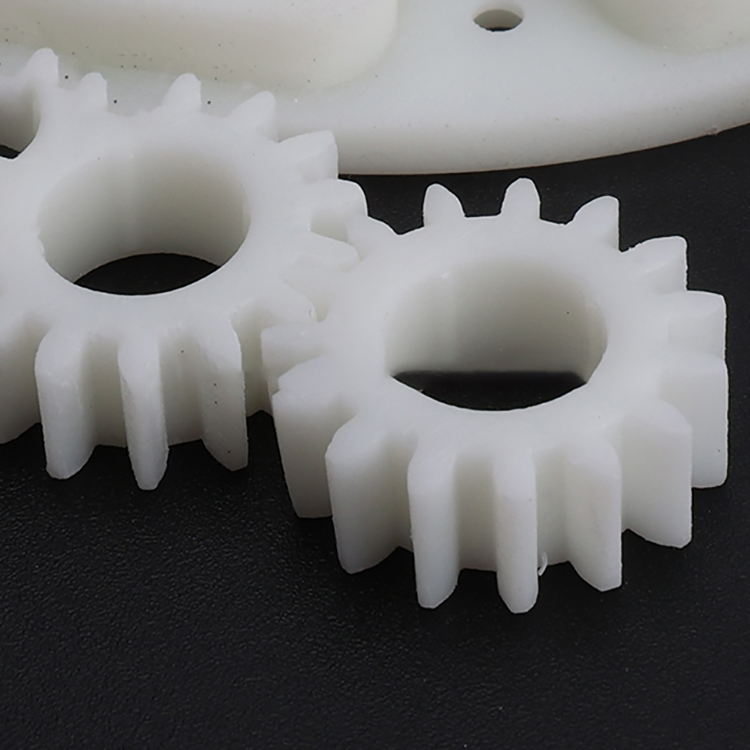

The Benefits of Using Plastic Nylon Hardware Components in Manufacturing Plastic nylon hardware components have become increasingly popular in the manufacturing industry due to their numerous benefits. These components are made from a type of thermoplastic polymer known as nylon, which is known for its durability, strength, and resistance to wear and tear. In this…