“Plastic production parts” and “plastic parts” generally refer to components or products that are manufactured using plastic materials. Here’s an overview:

1.Definition: Plastic parts are items made from various types of plastic materials through processes such as injection molding, extrusion, blow molding, or thermoforming. These parts can vary widely in size, shape, and complexity.

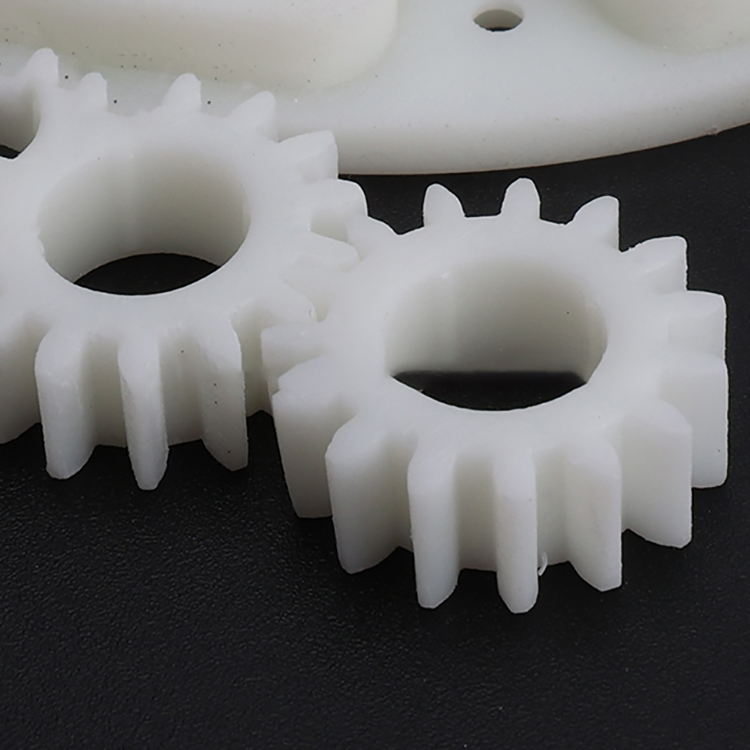

2.Types: Plastic parts can range from small, intricate components like gears and clips to larger items such as casings for electronic devices, automotive interior components, household goods, medical device enclosures, and more.

3.Manufacturing Processes:

4.Injection Molding: Most common method where molten plastic is injected into a mold cavity to form the desired shape.

5.Extrusion: Used for producing continuous lengths of plastic profiles or tubes.

6.Blow Molding: Utilized for hollow plastic parts like bottles and containers.

7.Thermoforming: Involves heating a plastic sheet until it becomes pliable and forming it over a mold to create the desired shape.

8.Applications: Plastic parts find applications across numerous industries including automotive, electronics, consumer goods, medical devices, aerospace, and more. They are chosen for their versatility, cost-effectiveness, durability, and ability to be molded into complex shapes.

9.Design Considerations: Designing plastic parts involves considerations such as material selection (thermoplastics or thermosets), part geometry, structural requirements, surface finish, tolerances, and manufacturability.

10.Quality and Standards: Manufacturers adhere to quality standards to ensure plastic parts meet specifications, including dimensional accuracy, strength, chemical resistance, and aesthetics.

If you need specific information about types of plastic parts or examples of their applications, feel free to ask!