Vacuum Casting

Vacuum casting, also called urethane casting or silicone molding, it is a fast and low-cost technology to create a prototype when you need multiple parts or multiple colors, it also to be used to closely simulate final molded parts or finished products.

How Does Vacuum Casting Work?

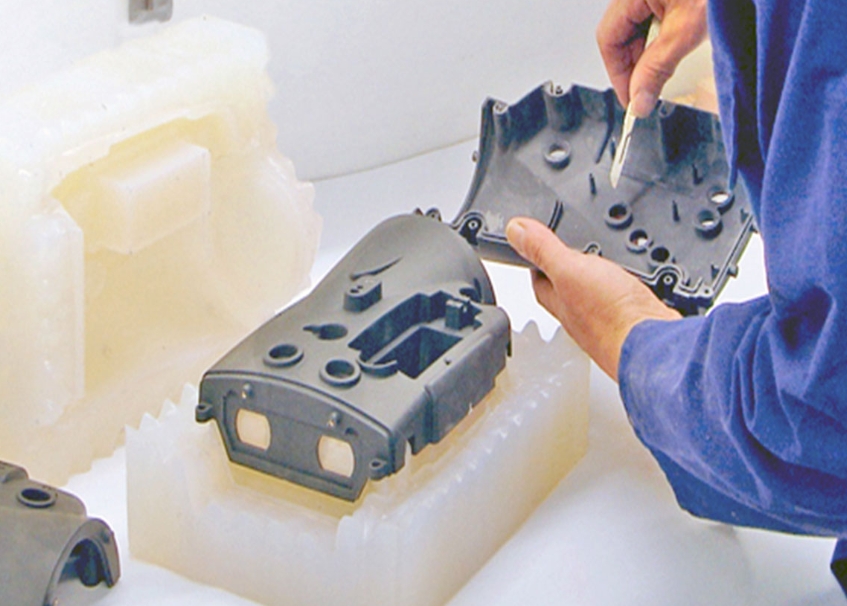

Generally, using CNC machining or SLA part as a master pattern first, and then create a mold which made from silicone material. The mold duplicate intricate details and textures from the master pattern. Then pour liquid casting material under precise vacuum into the mold, take the copy parts out of the mold and remove excess materials, finally get fine texture and colored parts one by one.

The Capability For The Vacuum Casting

HAOPROTO owns 4 sets of vacuum casting machines, which can cast prototypes with the max dimension up to 2200mm*1200mm *1000mm.

We can accurately reproduce the prototypes with original color,over-mold, texture and geometries from the master model and components. These plastic castings will closely represent the mechanical properties of the intended production parts from a steel mold. One silicone mold can cast about 15 to 20 pieces of parts, depends on complexity, painting or original color, size and other factors in different parts. The typical lead time is 7 working days for 10 parts.

Vacuum casting is widely used in various industries at HAOPROTO, such as automotive, consumer and medical industries.

Vacuum Casting Overmold at HAOPROTO

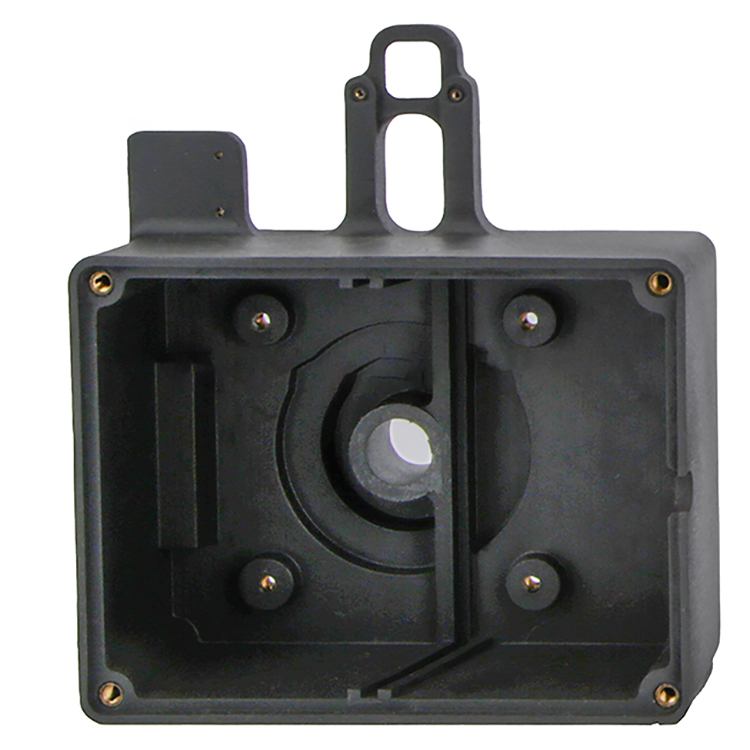

Overmolding is a multi-step Vacuum Casting process where two or more components are molded over top of one another, it is a two-step process. HAOPROTO provides different kinds of Vacuum Casting Overmold, such as rigid and rubber plastic overmold, metal and rigid plastic overmold, metal and rubber plastic overmold, and inserts overmold.

Ready For Your Next Project?

Welcome to our inquiry, we will provide you with a professional quotation as soon as possible.