플라스틱 사출성형기 부품의 종류와 용도 알아보기

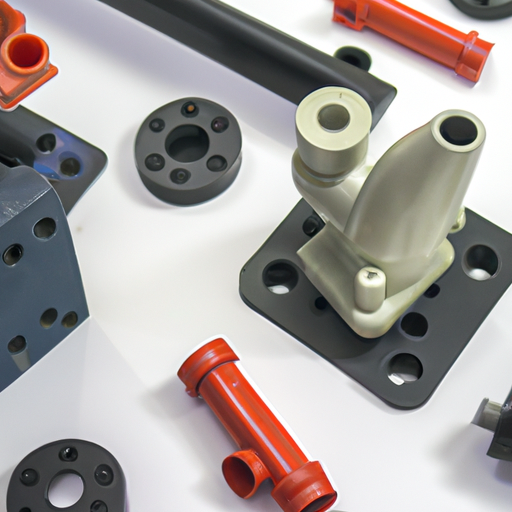

The Advantages of Insert Molding for Plastic Parts Insert molding is a highly efficient and cost-effective method for manufacturing plastic parts. It involves the process of inserting a pre-formed component, such as a metal insert or another piece of plastic, into a mold cavity before injecting molten plastic around it. This technique offers numerous advantages…

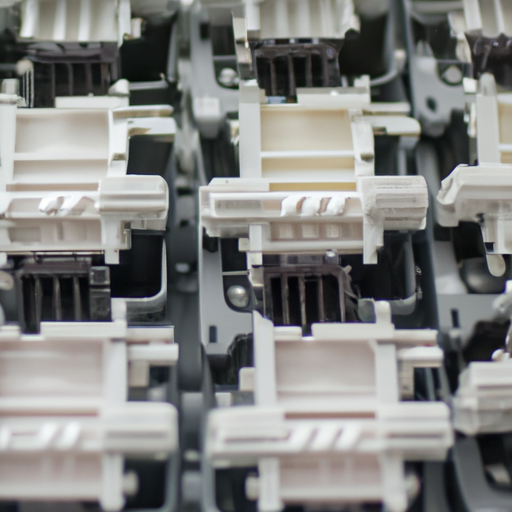

Benefits of Using Transparent Plastic Electronic Component Parts Transparent plastic electronic component parts are becoming increasingly popular in the electronics industry due to their numerous benefits. These parts are made from high-quality plastic materials that allow for easy visibility of the internal components of electronic devices. In this article, we will explore the advantages of…

베르세파두 셀라탄 터미널의 편의성 탐색: 이용 가능한 서비스 및 편의시설 안내 Bersepadu Selatan 터미널이 말레이시아 대중교통을 어떻게 재정의하고 있는가 제조과정 주문-원자재-생산-품질검사-포장-출하 우리의 서비스 OEM/ODM

The Benefits of Using Plastic Components Parts in Guangzhou Manufacturing Plastic components parts play a crucial role in the manufacturing industry, especially in a city like Guangzhou, known for its booming manufacturing sector. These parts are essential for creating a wide range of products, from electronics to automotive components. There are several benefits to using…

플라스틱 성형기 부품의 주요 구성요소 이해 플라스틱 성형기는 플라스틱 제품 생산을 위해 다양한 산업 분야에서 널리 사용되고 있습니다. 이러한 기계는 기계의 원활하고 효율적인 작동을 보장하기 위해 함께 작동하는 몇 가지 주요 구성 요소로 구성됩니다. 이러한 구성 요소를 이해하는 것은 플라스틱 성형 기계를 사용하거나 작동하는 모든 사람에게 필수적입니다. 플라스틱 성형 기계의 가장 중요한 구성 요소 중…

Common Types of Plastic Part Defects and How to Prevent Them Plastic parts are widely used in various industries, from automotive to electronics, due to their versatility and cost-effectiveness. However, like any manufacturing process, there is always a risk of defects occurring during the production of plastic parts. These defects can lead to product failures,…