Pressure Die Casting Service

What is pressure die casting?

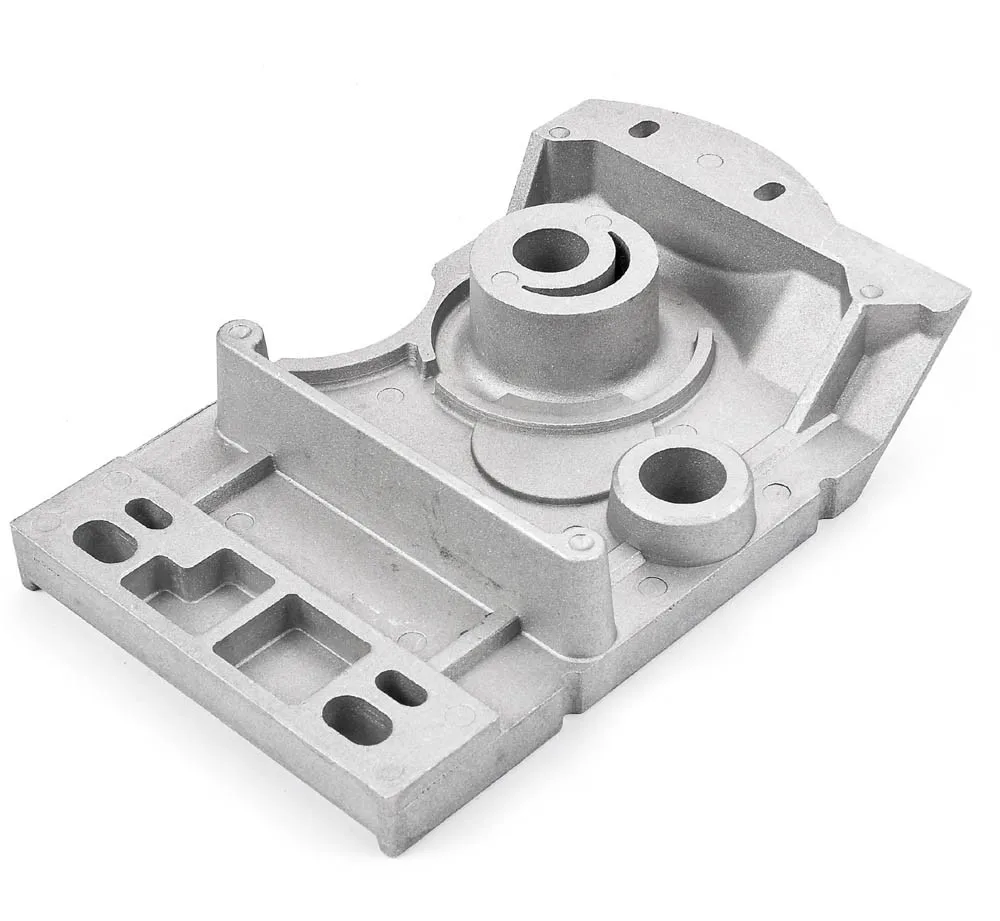

Pressure die casting is an efficient manufacturing method for producing metal components , which is use high-intensity pressure and speed to forces the molten metal into a closed steel die cavity. It is suitable for high volume production projects. HAOPROTO can offer metal die casting service for prototype, low-volume and series production projects.

What industries die casting apply in?

Die casting is widely used in various industries, such as automotive, consumer, medicalmedical and industrial products. At HAOPROTO, we have rich experience with manufacturing car components, medicalmedical products etc.

What are the common materials for HAOPROTO’s pressure die casting service?

Aluminum die casting

The one of the most popular die casting material is aluminum. It has the advantages of lightweight, high operating temperatures resistance, good corrosion-resistant, and easy to cast, and is very popular in the production of things like industrial components, automobile parts and much more. At SuNPe, the most common aluminum materials are ADC12, A380 and A356-T6.

Zinc die casting

Compared with aluminum material, zinc has heightened thermal conductivity. Also, with low melting point, it can help to extend the mold life, which is the key factor that it can be widely used on medical equipment. Zinc#3, zinc#4 and zinc#5 are the common materials at HAOPROTO.

Magnesium die casting

Magnesium is the lightest alloy commonly die casting, and can offer excellent strength-to-weight ratio. Furthermore, it has good EMI and RFI shielding properties, which is the most suitable material to produce connectors and electrical housings. Not only that, it is used in a wide range of applications, it is also often used in medical and laboratory equipment because it can protect against interfering signals.

Why choose HAOPROTO’s die casting service?

Multiple material options: At HAOPROTO, we can offer zinc 3#, zinc 4#, zinc 5#, ADC12, A380, A356-T6, AZ91DMg materials die casting.

No MOQ: There are no MOQ at HAOPROTO, we can offer services from 1 piece to hundreds of thousands of quantity. No matter series production projects or prototype projects, all can be satisfied well.

Strict quality system: At HAOPROTO, the basic quality system we follow is the ISO 9001 Certified Manufacturing, and we follow the IATF16949 for automotive project , the ISO13485 standard for medical devices project.

Great secondary operations capacity: At HAOPROTO, we can offer post machined to achieve all the criteria of tolerances and help to realize the forming. Also, there are many kinds of surface finishing can help to realize products appearance and functional requirement.

Ready For Your Next Project?

Welcome to our inquiry, we will provide you with a professional quotation as soon as possible.