Hur potmetrar används i instrumentplastkomponenter: en guide till deras fördelar och tillämpningar

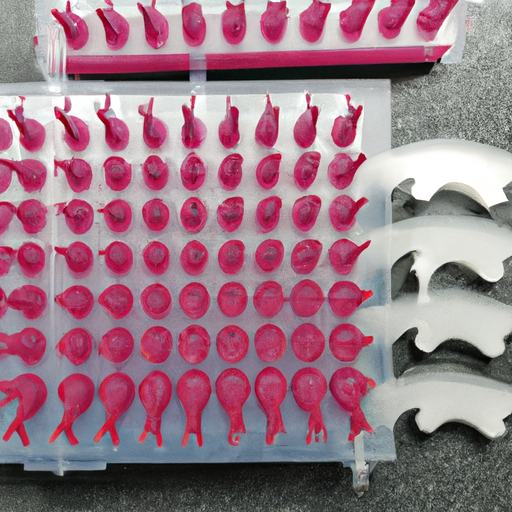

| Produktnamn | OEM Formsprutning av plast Delar |

| Ritningsformat | 2D(PDF/CAD) Och 3D(STP/STEP) |

| Produktnamn | OEM Formsprutning av plast Delar |

| Ritningsformat | 2D(PDF/CAD) Och 3D(STP/STEP) |

The Benefits of Using King Plastic Pte Ltd for Your Plastic Manufacturing Needs Exploring the Innovative Technologies Used by King Plastic Pte Ltd to Create High-Quality Plastic Products Product Name OEM Plastic injection molding Parts Drawing Formats 2D(PDF/CAD) And 3D(STP/STEP)

Fördelarna med att använda specialanpassade antistatiska kammar av plast för värmebeständighet Anpassad avskiljande plast antistatiska kammar för värmebeständighet När det kommer till styling av vårt hår, förlitar vi oss ofta på olika verktyg och produkter för att uppnå önskat utseende. Ett sådant verktyg som har vunnit popularitet de senaste åren är den anpassade antistatiska kammen…

The Advantages of Using Plastic Auto Parts Plastic auto parts have become increasingly popular in the automotive industry due to their numerous advantages. From improved fuel efficiency to enhanced safety features, plastic auto parts offer a range of benefits that make them a preferred choice for manufacturers and consumers alike. One of the primary advantages…

Gör-det-själv plastgjutning: Hur du skapar dina egna plastdelar hemma. Plastgjutning är ett utmärkt sätt att skapa anpassade delar för dina projekt. Med rätt verktyg och material kan du göra dina egna plastdelar hemma. I det här blogginlägget kommer vi att diskutera grunderna för plastgjutning, de material du behöver och de steg du måste ta för…

Vikten av designöverväganden i plastformsprutningskomponenter Plastformsprutning är en mycket använd tillverkningsprocess för att tillverka plastkomponenter. Det går ut på att spruta in smält plast i en formhålighet, låta den svalna och stelna, och sedan mata ut den färdiga produkten. Denna process är känd för sin effektivitet, kostnadseffektivitet och förmåga att producera komplexa former med hög…

Vikten av att välja en pålitlig OEM-tillverkare av plastdelar Vikten av att välja en pålitlig tillverkare av plastdelar OEM När det kommer till tillverkning av plastdelar är det avgörande att välja rätt OEM (Original Equipment Manufacturer). Kvaliteten på plastdelarna som används i olika industrier kan avsevärt påverka slutproduktens totala prestanda och hållbarhet. Därför är det…