How Potmeters are Used in Instrument Plastic Components: A Guide to Their Benefits and Applications

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

The Benefits of Using Plastic Injection Mold Parts for Your Manufacturing Process When it comes to manufacturing parts for your products, plastic injection molding is one of the most efficient and cost-effective methods available. This process involves injecting molten plastic into a mold to create a part with a specific shape and size. The benefits…

The Benefits of Buying Motorcycle Plastic Parts Online Buying motorcycle plastic parts online can be a great way to save time and money. With the convenience of online shopping, you can find the parts you need quickly and easily, without having to leave the comfort of your home. Additionally, online stores often offer competitive prices…

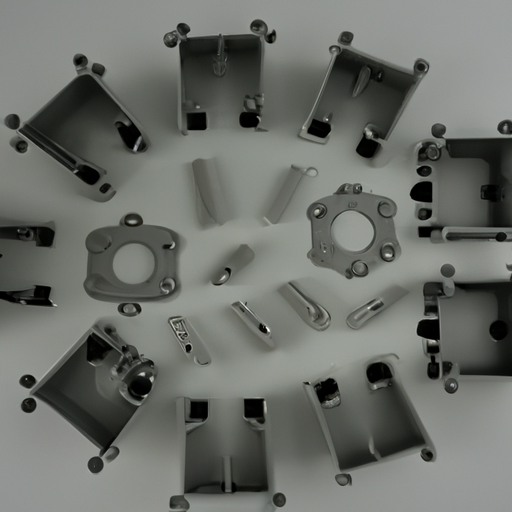

CNC Aluminum Parts and Aluminum CNC Milling Parts: An In-Depth Exploration Introduction 1. Characteristics of Aluminum and CNC Machining 1.1 Aluminum Material Properties Aluminum is renowned for its combination of properties that make it ideal for various applications: Lightweight: With a density approximately one-third that of steel, aluminum is ideal for applications where weight reduction…

The Advantages of Plastic Molding Parts in Manufacturing Processes Plastic molding parts have become an integral component in the manufacturing processes of various industries. From automotive to electronics, these parts offer numerous advantages that make them a preferred choice for manufacturers. In this article, we will explore the advantages of plastic molding parts and how…

Dashboard When you think about the components that make up a car, the dashboard is often one of the first things that come to mind. The dashboard is not only a functional part of the vehicle but also serves as a focal point for the driver, providing important information and controls within easy reach. In…

Advantages of Injection Moulded Plastic Components in Manufacturing Processes Injection moulded plastic components have become an integral part of the manufacturing industry. With their numerous advantages, they have revolutionized the way products are made. In this article, we will explore the advantages of injection moulded plastic components in manufacturing processes. One of the key advantages…