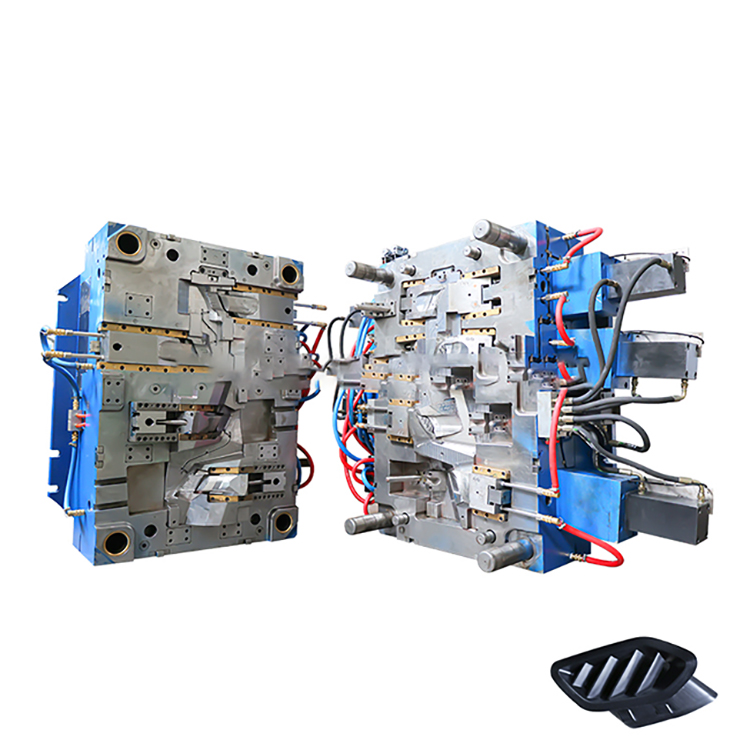

The Advantages of Plastic Molding Parts in Manufacturing Processes

Plastic molding parts have become an integral component in the manufacturing processes of various industries. From automotive to electronics, these parts offer numerous advantages that make them a preferred choice for manufacturers. In this article, we will explore the advantages of plastic molding parts and how they contribute to the efficiency and effectiveness of manufacturing processes.

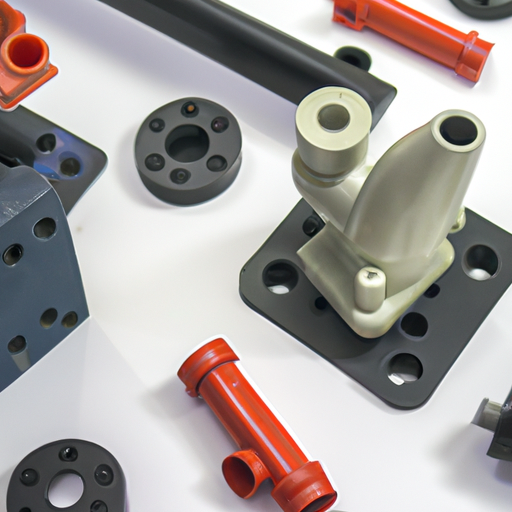

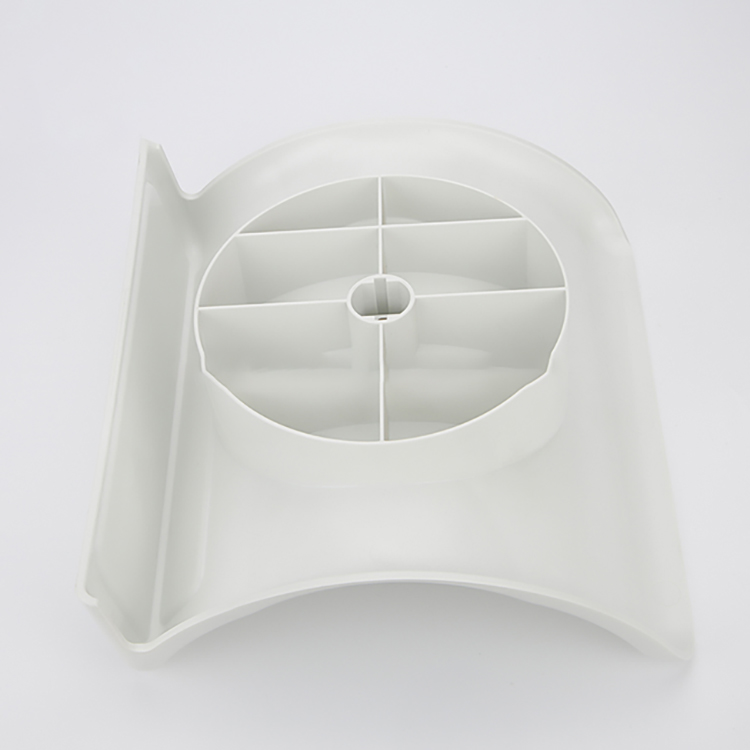

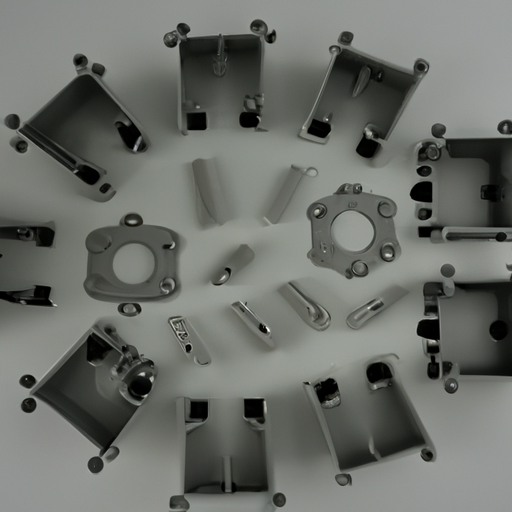

One of the key advantages of plastic molding parts is their versatility. Plastic can be molded into a wide range of shapes and sizes, allowing manufacturers to create complex and intricate designs. This flexibility opens up endless possibilities for product development and innovation. Whether it’s a small component or a large structural part, plastic molding can deliver the desired shape and dimensions with precision.

In addition to versatility, plastic molding parts offer excellent strength and durability. Modern plastic materials are engineered to withstand harsh conditions, making them suitable for a variety of applications. Whether it’s exposure to extreme temperatures, chemicals, or physical stress, plastic molding parts can maintain their integrity and functionality. This durability ensures that products can withstand the rigors of everyday use, providing long-lasting performance and reliability.

Another advantage of plastic molding parts is their cost-effectiveness. Plastic materials are generally more affordable compared to other materials like metal or glass. Additionally, the molding process itself is highly efficient, allowing for mass production at a lower cost per unit. This cost advantage makes plastic molding parts an attractive option for manufacturers looking to optimize their production processes and reduce overall expenses.

Furthermore, plastic molding parts offer excellent design flexibility. Manufacturers can easily incorporate various features and details into their products, such as threads, undercuts, or logos. This design flexibility allows for the integration of multiple functions into a single part, reducing the need for additional components. By consolidating parts, manufacturers can simplify assembly processes, reduce production time, and minimize the risk of errors or defects.

Plastic molding parts also contribute to sustainability efforts in manufacturing. Plastic materials can be recycled and reused, reducing waste and minimizing the environmental impact. Additionally, the molding process itself generates less waste compared to other manufacturing methods. This eco-friendly aspect of plastic molding parts aligns with the growing demand for sustainable and environmentally conscious practices in the industry.

Lastly, plastic molding parts offer excellent consistency and repeatability. The molding process ensures that each part produced is identical to the next, maintaining consistent quality and performance. This consistency is crucial in industries where precision and reliability are paramount, such as automotive or aerospace. Manufacturers can rely on plastic molding parts to meet strict specifications and standards consistently.

| Product Name | OEM Plastic injection molding Parts |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

| Our Services | OEM/ODM |

In conclusion, plastic molding parts offer numerous advantages in manufacturing processes. Their versatility, strength, and durability make them suitable for a wide range of applications. The cost-effectiveness, design flexibility, and sustainability aspects further enhance their appeal to manufacturers. Additionally, the consistency and repeatability of plastic molding parts ensure high-quality products that meet industry standards. As the demand for efficient and reliable manufacturing processes continues to grow, plastic molding parts will undoubtedly play a crucial role in meeting these requirements.