Table of Contents

The Benefits of Using Plastic Parts for Automotive Applications

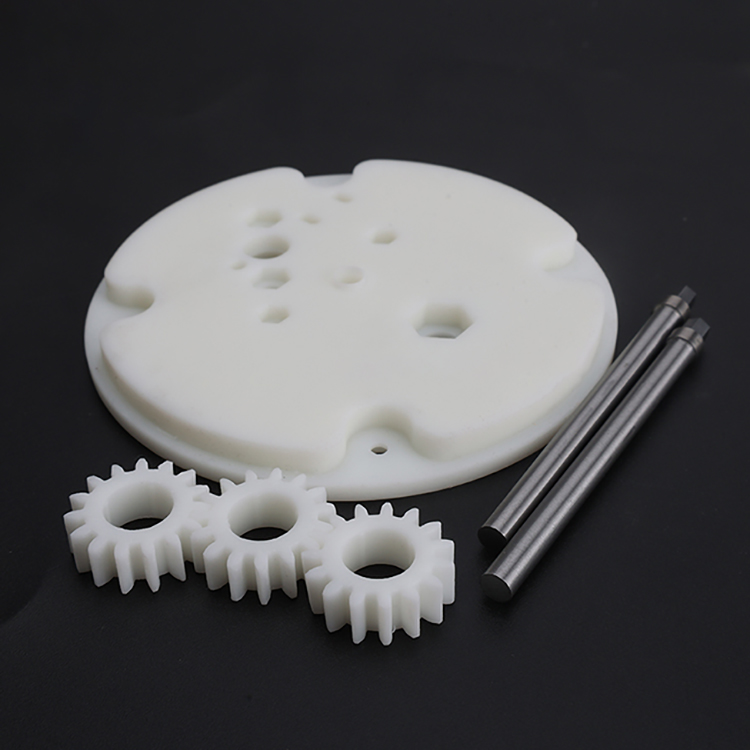

The use of plastic parts in automotive applications has become increasingly popular in recent years due to its numerous advantages. Plastic parts are lightweight, durable, and cost-effective, making them an ideal choice for many automotive applications. In addition, plastic parts are highly customizable and can be designed to meet specific requirements.

One of the primary benefits of using plastic parts for automotive applications is their lightweight nature. Plastic parts are much lighter than metal parts, which can reduce the overall weight of the vehicle and improve fuel efficiency. This can result in significant cost savings over the life of the vehicle. Additionally, the lighter weight of plastic parts can reduce the strain on the engine and other components, resulting in improved performance and reliability.

Another advantage of using plastic parts for automotive applications is their durability. Plastic parts are resistant to corrosion, rust, and other environmental factors, making them ideal for use in harsh conditions. This can help to extend the life of the vehicle and reduce the need for costly repairs. Additionally, plastic parts are often designed to be flexible, allowing them to absorb shock and vibration, which can help to reduce wear and tear on the vehicle.

Finally, plastic parts are highly customizable and can be designed to meet specific requirements. This allows for greater flexibility in design and can help to reduce costs. Additionally, plastic parts can be easily molded into complex shapes, allowing for greater design freedom. This can help to create unique and innovative designs that can improve the performance and aesthetics of the vehicle.

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Our Services | OEM/ODM |

Overall, the use of plastic parts for automotive applications offers numerous benefits. Plastic parts are lightweight, durable, and cost-effective, making them an ideal choice for many automotive applications. Additionally, plastic parts are highly customizable and can be designed to meet specific requirements. This allows for greater flexibility in design and can help to reduce costs. Finally, plastic parts can be easily molded into complex shapes, allowing for greater design freedom. All of these benefits make plastic parts an ideal choice for automotive applications.