Table of Contents

Benefits of Using High-Quality Plastic Injection Moulding Machine Parts

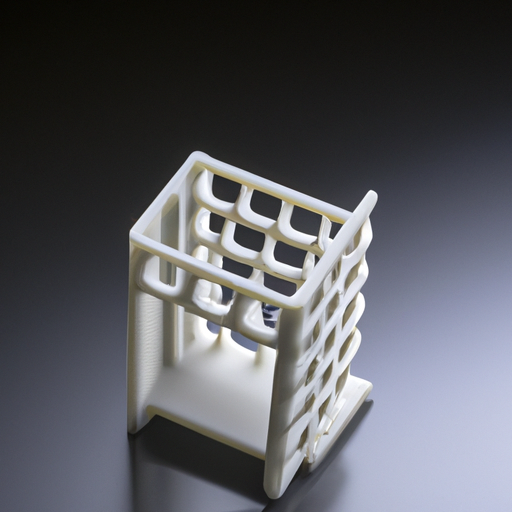

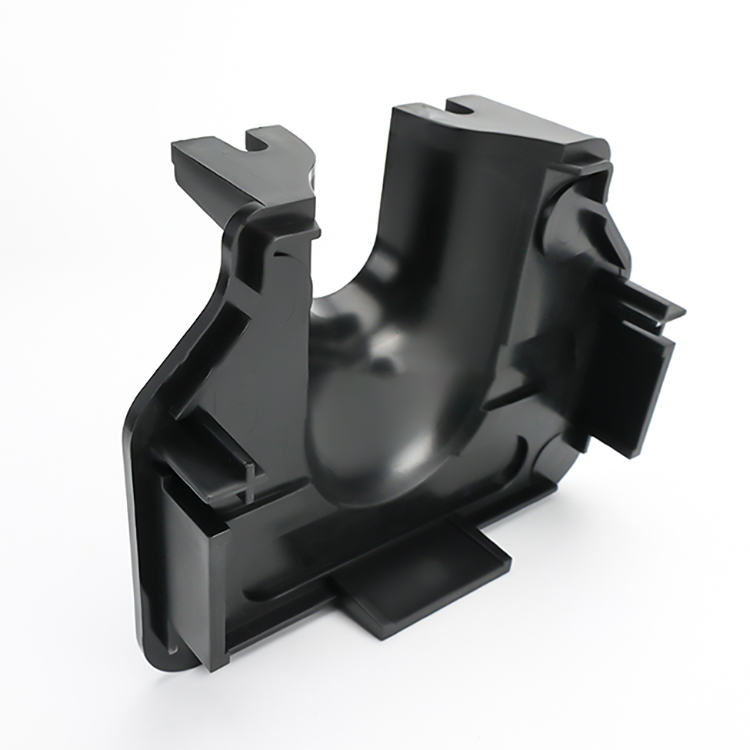

Plastic injection moulding is a widely used manufacturing process that involves injecting molten plastic material into a mould cavity. This process is used to produce a wide range of plastic products, from small components to large parts. One of the key components of a plastic injection moulding machine is its parts. The quality of these parts can have a significant impact on the overall performance and efficiency of the machine.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

Using high-quality plastic injection moulding machine parts offers a number of benefits. One of the main advantages is improved durability and longevity. High-quality parts are made from superior materials that are designed to withstand the high pressures and temperatures involved in the injection moulding process. This means that they are less likely to wear out or break down, resulting in fewer maintenance issues and downtime for the machine.

Another benefit of using high-quality plastic injection moulding machine parts is improved precision and accuracy. The quality of the parts can have a direct impact on the quality of the finished products. Parts that are made to tight tolerances and specifications will result in more consistent and precise moulding, leading to higher quality products. This can help to reduce waste and improve overall production efficiency.

In addition to improved durability and precision, high-quality plastic injection moulding machine parts can also help to improve energy efficiency. Parts that are well-designed and properly manufactured can help to reduce energy consumption and operating costs. This can result in significant savings over time, making it a cost-effective investment for manufacturers.

Furthermore, using high-quality plastic injection moulding machine parts can also help to improve safety in the workplace. Inferior parts can pose a safety risk to operators and other personnel working with the machine. By using high-quality parts that are designed and manufactured to meet strict safety standards, manufacturers can help to create a safer working environment for their employees.

Overall, the benefits of using high-quality plastic injection moulding machine parts are clear. From improved durability and precision to energy efficiency and safety, investing in high-quality parts can have a positive impact on the performance and efficiency of a plastic injection moulding machine. Manufacturers who want to maximize the potential of their machines and produce high-quality products should consider using high-quality parts for their injection moulding machines. By doing so, they can ensure that their machines operate at peak performance and deliver consistent, high-quality results.

Common Issues and Solutions for Plastic Injection Moulding Machine Parts

Plastic injection moulding machines are essential tools in the manufacturing industry, used to produce a wide range of plastic products. These machines consist of various parts that work together to create the final product. However, like any other machinery, plastic injection moulding machines can experience issues that can affect their performance. In this article, we will discuss some common issues that can arise with plastic injection moulding machine parts and provide solutions to address them.

One common issue that can occur with plastic injection moulding machine parts is wear and tear. Over time, the constant use of the machine can cause parts to become worn out or damaged, leading to a decrease in performance. To address this issue, regular maintenance and inspection of the machine parts are essential. By identifying and replacing worn-out parts promptly, you can prevent further damage to the machine and ensure its continued operation.

Another common issue that can affect plastic injection moulding machine parts is overheating. This can be caused by a variety of factors, such as a malfunctioning cooling system or excessive friction between moving parts. To prevent overheating, it is important to ensure that the cooling system is functioning correctly and that all moving parts are properly lubricated. Additionally, monitoring the temperature of the machine during operation can help identify any potential issues before they escalate.

Inconsistent product quality is another issue that can arise with plastic injection moulding machine parts. This can be caused by a variety of factors, such as improper alignment of the mould, worn-out or damaged parts, or fluctuations in temperature or pressure. To address this issue, it is important to regularly inspect and maintain the machine parts, ensuring that they are in good working condition. Additionally, adjusting the settings of the machine to optimize the production process can help improve product quality.

One of the most serious issues that can occur with plastic injection moulding machine parts is a breakdown. This can be caused by a variety of factors, such as a malfunctioning motor, a faulty electrical system, or a damaged mould. In the event of a breakdown, it is important to address the issue promptly to minimize downtime and prevent further damage to the machine. Having a maintenance plan in place and keeping spare parts on hand can help ensure that the machine can be quickly repaired and returned to operation.

In conclusion, plastic injection moulding machine parts are essential components of the manufacturing process, and it is important to address any issues that may arise promptly. By regularly inspecting and maintaining the machine parts, monitoring the temperature and performance of the machine, and addressing any issues that arise promptly, you can ensure that your plastic injection moulding machine operates efficiently and produces high-quality products. Remember, prevention is always better than cure when it comes to maintaining plastic injection moulding machine parts.