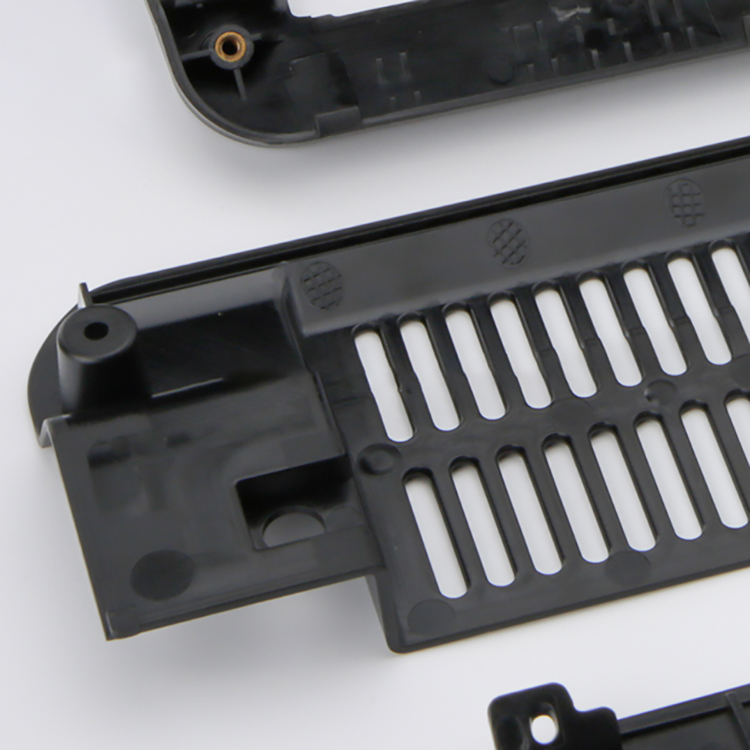

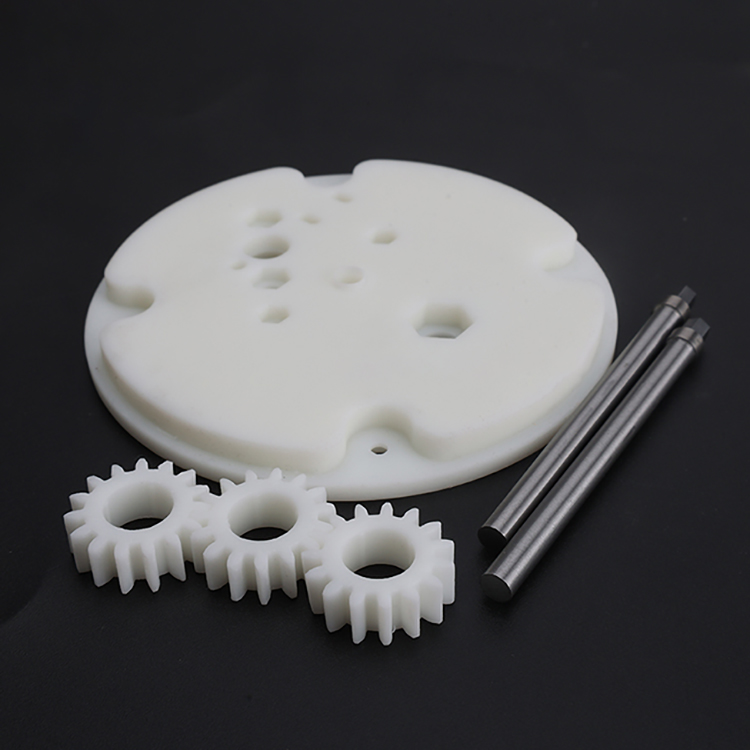

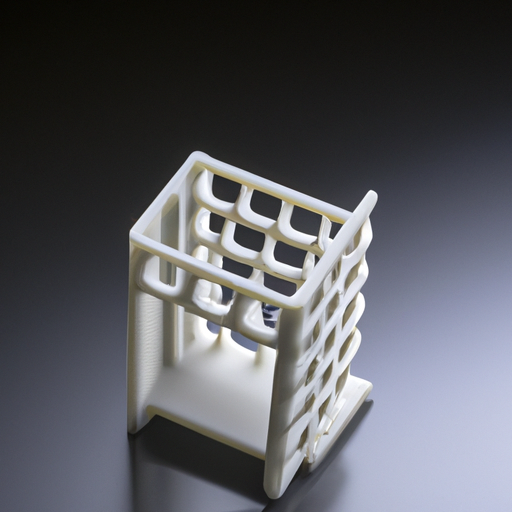

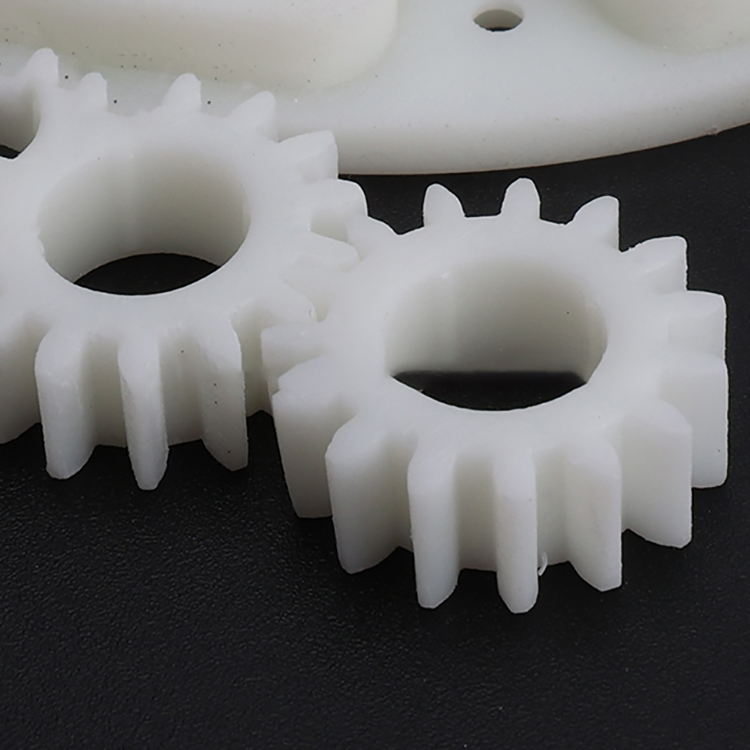

plastic parts manufacturing plastic parts crystal coating

Understanding Plastic Parts Manufacturing and Crystal Coating 1. Introduction In the modern manufacturing landscape, plastic parts are ubiquitous due to their versatility, durability, and cost-effectiveness. However, to meet the diverse demands of various industries, manufacturers continuously seek ways to enhance the functionality and appearance of these plastic components. One such enhancement is crystal coating, a…