Table of Contents

Exploring the Benefits of Plastic Injection Mould Components for Manufacturing

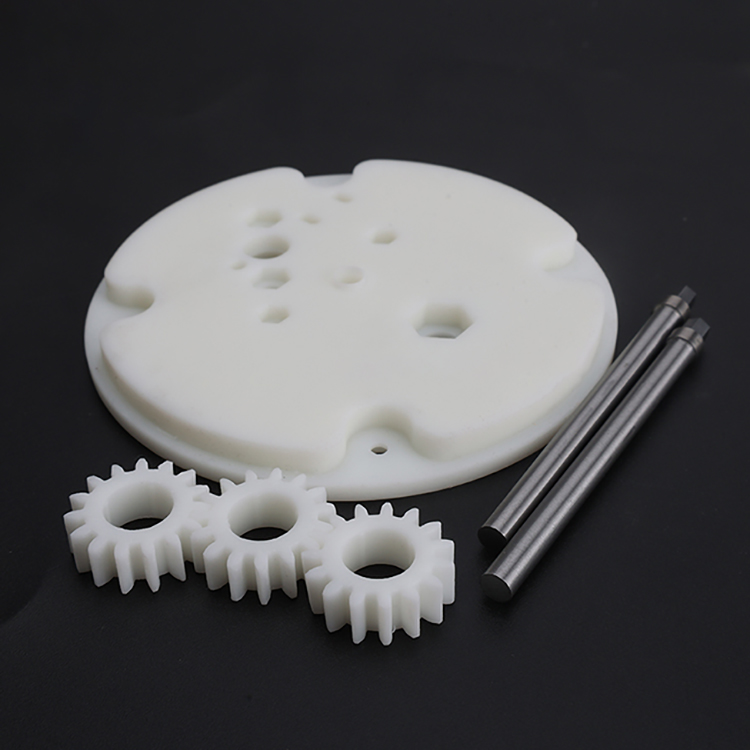

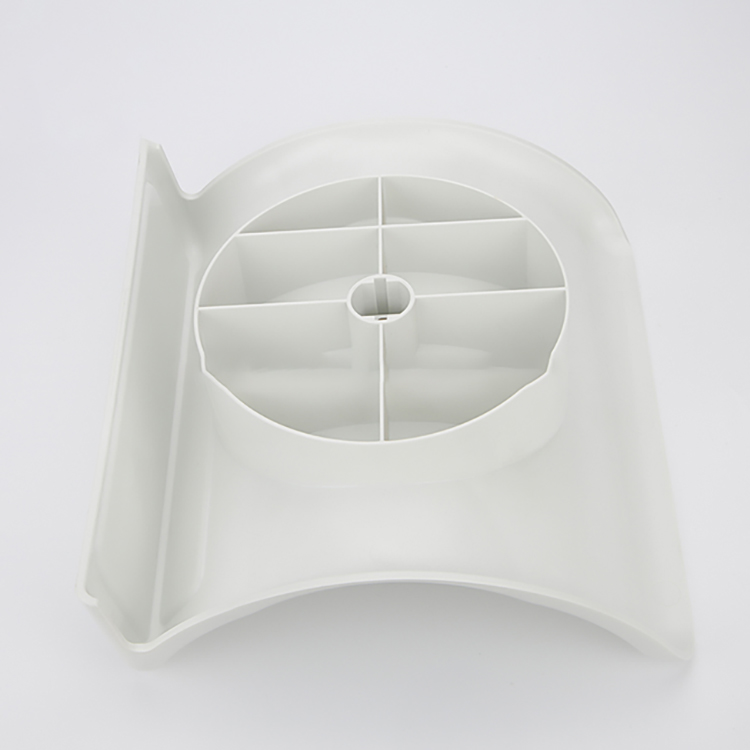

Plastic injection mould components are becoming increasingly popular in the manufacturing industry due to their many benefits. These components are used to create a variety of products, from medical devices to automotive parts. Injection moulding is a process that involves injecting molten plastic into a mould to create a desired shape. This process is fast, efficient, and cost-effective, making it an ideal choice for many manufacturers.

One of the main benefits of using plastic injection mould components is that they are highly durable and can withstand extreme temperatures and pressures. This makes them ideal for use in a variety of applications, from medical devices to automotive parts. Additionally, plastic injection mould components are highly customizable, allowing manufacturers to create products that meet their exact specifications.

Another benefit of using plastic injection mould components is that they are relatively inexpensive. This makes them an attractive option for manufacturers who are looking to reduce costs. Additionally, plastic injection mould components are easy to use and require minimal maintenance. This makes them a great choice for manufacturers who are looking to streamline their production process.

Finally, plastic injection mould components are environmentally friendly. The process of injection moulding does not produce any hazardous waste, making it a great choice for manufacturers who are looking to reduce their environmental impact. Additionally, plastic injection mould components can be recycled, further reducing their environmental impact.

Overall, plastic injection mould components offer a variety of benefits for manufacturers. They are highly durable, customizable, cost-effective, easy to use, and environmentally friendly. As such, they are becoming increasingly popular in the manufacturing industry.

Understanding the Design Considerations for Plastic Injection Mould Components

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |