Erkundung der verschiedenen Arten von Kunststoffspritzgussmaschinenkomponenten und ihrer Verwendung

The Benefits of Using ABS Building Products for Construction Projects ABS Building Products Pte Ltd is a leading provider of construction materials that are widely used in various construction projects. With a wide range of products available, ABS Building Products has become a trusted name in the industry. In this article, we will explore the…

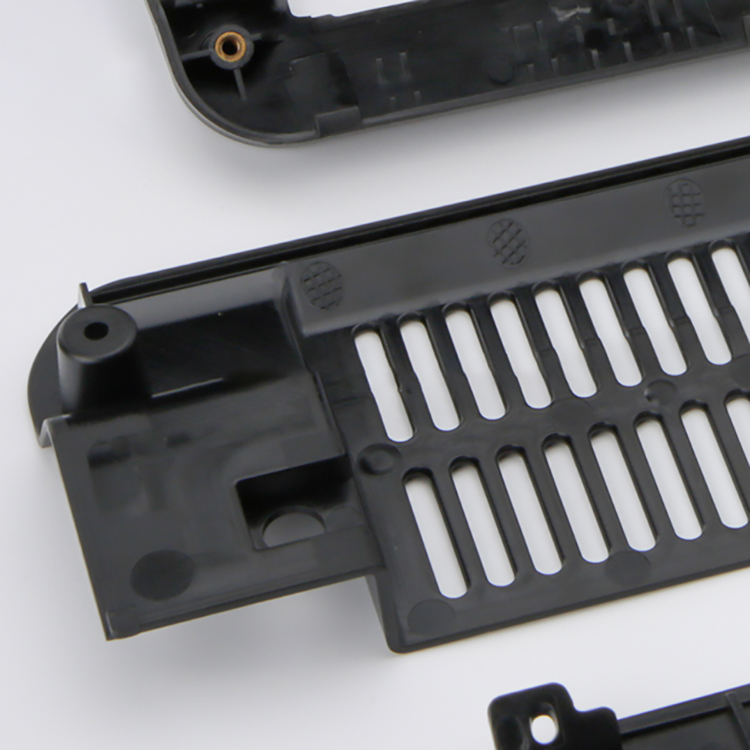

ABS injection molding is commonly used to manufacture plastic parts for various applications, including car mount holders. ABS (Acrylonitrile Butadiene Styrene) is chosen for its strength, impact resistance, and affordability, making it suitable for products that require durability and a smooth finish.When producing ABS plastic parts for car mount holders through injection molding, manufacturers typically…

Die Vorteile des Online-Kaufs von Motorrad-Kunststoffteilen Der Online-Kauf von Motorrad-Kunststoffteilen kann eine großartige Möglichkeit sein, Zeit und Geld zu sparen. Mit dem Komfort des Online-Einkaufs können Sie die Teile, die Sie benötigen, schnell und einfach finden, ohne Ihr Zuhause verlassen zu müssen. Darüber hinaus bieten Online-Shops oft wettbewerbsfähige Preise und Rabatte an, was es einfacher…

When discussing plastic mould companies and the steel used in plastic moulding, it’s essential to understand the critical role that both play in the manufacturing process. Here’s a detailed look into both aspects: Plastic Mould Companies Plastic mould companies specialize in designing, manufacturing, and maintaining moulds used in the injection moulding process. These companies provide…

So identifizieren und reparieren Sie gängige Autoteile aus Kunststoff Das Identifizieren und Reparieren gängiger Autoteile aus Kunststoff kann für viele Autobesitzer eine entmutigende Aufgabe sein. Mit den richtigen Kenntnissen und Werkzeugen kann es jedoch ein relativ unkomplizierter Prozess sein. In diesem Artikel besprechen wir, wie man gängige Autoteile aus Kunststoff identifiziert und repariert. Produktionsprozess Bestellungen-Rohstoffe-Produktion-Qualitätsprüfung…

Erkunden Sie die Annehmlichkeiten des Terminals Bersepadu Selatan: Ein Leitfaden zu den verfügbaren Diensten und Annehmlichkeiten Wie der Terminal Bersepadu Selatan den öffentlichen Nahverkehr in Malaysia neu definiert Produktionsprozess Bestellungen-Rohstoffe-Produktion-Qualitätsprüfung -Verpackung-Versand Unsere Dienstleistungen OEM/ODM