さまざまな種類のプラスチック射出成形機のコンポーネントとその用途を探る

耐熱用カスタムパーティングプラスチック帯電防止コームのメリット カスタム分け用プラスチック帯電防止コームを使用する主な利点の 1 つは、高温に耐えられることです。熱にさらされると溶けたり歪んだりする可能性がある通常のコームとは異なり、これらのコームは熱に耐えるように特別に設計されています。これは、ストレートアイロンやヘアアイロンなどの熱いスタイリングツールで使用しても損傷したり効果がなくなったりすることがなく、安心して使用できることを意味します。 カスタム分け目プラスチック帯電防止コームは、耐熱性に加えて帯電防止機能も備えています。プロパティ。これは、縮れた髪やくせのある髪を持つ人に特に有益です。これらのコームの帯電防止特性は、ヒート スタイリング ツールを使用するときによくある問題である静電気を軽減するのに役立ちます。カスタムの分け目用プラスチック帯電防止コームを使用すると、髪の飛び散りに別れを告げ、滑らかで滑らかな髪を手に入れることができます。 配送について PEバッグ + 紙カード/紙スキン + 輸出用カートン / クレート / パレット 表面仕上げ 研磨仕上げ / スリックプリント / テクスチャ仕上げ / ラバー塗装 / 光沢仕上げ / 塗装 / スリックスクリーン / パッド印刷 / EMI コーティング / 電子メッキ / レーザーマーキング / など さらに、これらのコームはカスタマイズ可能で、ニーズに合わせて最適なデザインとサイズを選択できます。もつれをほぐすために歯の広いコームを好むか、正確なスタイリングのために歯の細かいコームを好むかにかかわらず、あなたの好みに合うカスタム分け目プラスチック帯電防止コームがあります。このレベルのカスタマイズにより、ツールの品質を損なうことなく、目的の結果を確実に達成できます。 カスタム分割プラスチック帯電防止コームを使用するもう 1 つの利点は、その耐久性です。高品質の素材で作られたこれらのコームは、長持ちするように作られています。破損しにくく、効果を損なうことなく通常の使用に耐えることができます。これは、カスタム分け目プラスチック帯電防止コームを今後何年も信頼できることを意味し、ヘア愛好家にとって価値のある投資になります。 耐久性に加えて、これらのコームは掃除やメンテナンスも簡単です。木材や金属などの他の素材で作られたコームとは異なり、プラスチック製のカスタム分割型帯電防止コームは、温水と中性洗剤で簡単に洗うことができます。これにより、コームが衛生的に保たれ、製品の蓄積がなく、使用するたびに最適なパフォーマンスが得られます。 結論として、耐熱性のためにカスタム分け用プラスチック帯電防止コームを使用する利点は数多くあります。高温に耐える能力から帯電防止特性まで、これらのコームはヒート スタイリング ツールを頻繁に使用する人にさまざまな利点をもたらします。カスタマイズのオプション、耐久性、メンテナンスの容易さが、その魅力をさらに高めます。したがって、完璧なヘアスタイルを達成するのに役立つ信頼性が高く効果的なツールをお探しの場合は、カスタム分け目プラスチック帯電防止コームへの投資を検討してください。あなたの髪はあなたに感謝するでしょう。 Furthermore, these combs are customizable,…

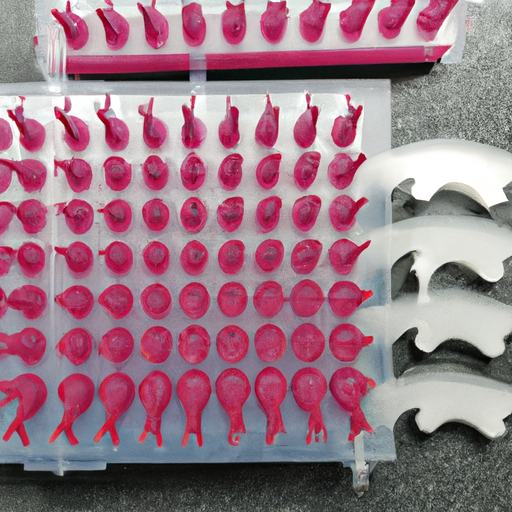

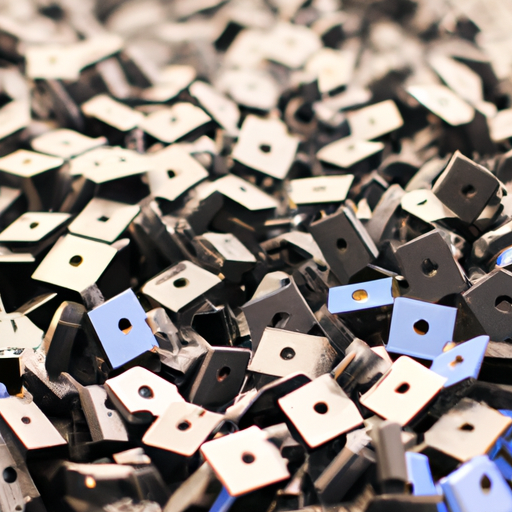

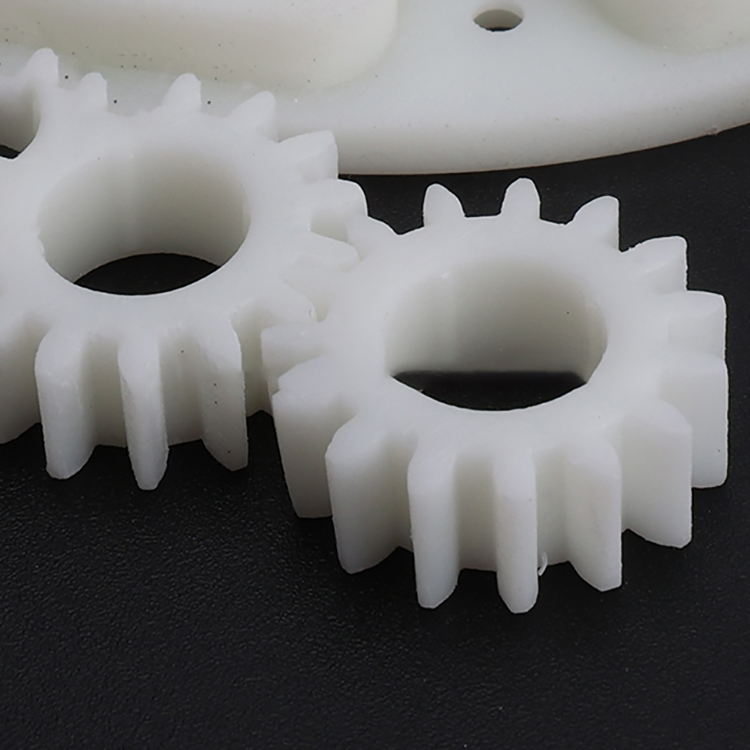

製造における計装用プラスチック部品の重要性 製造における計器用プラスチック部品の重要性 製造の世界において、計器用プラスチック部品は重要な役割を果たします。これらのコンポーネントは、自動車、航空宇宙、エレクトロニクス、医療などの幅広い業界で使用されています。これらは、耐久性、柔軟性、費用対効果を提供するため、さまざまな機器や機器の製造に不可欠です。 機器用プラスチック コンポーネントが非常に重要である主な理由の 1 つは、その多用途性です。プラスチックはさまざまな形状やサイズに成形できるため、メーカーは特定の用途に合わせてカスタマイズされたコンポーネントを作成できます。この柔軟性は、医療機器や航空宇宙機器など、精度と精度が最優先される業界で特に価値があります。 さらに、プラスチック コンポーネントは優れた耐久性を備えています。極端な温度、化学薬品、紫外線などの過酷な環境条件に耐えることができます。そのため、さまざまな要素にさらされる屋外機器、自動車部品、電子機器などでの使用に最適です。プラスチック コンポーネントは、衝撃や摩耗に対する高い耐性も備えているため、寿命と信頼性が保証されます。 計器用プラスチック コンポーネントのもう 1 つの重要な利点は、軽量であることです。金属部品と比較して、プラスチック部品は非常に軽いため、取り扱いや輸送が容易になります。この軽量化は、機器や装置の全体的な性能に大きな影響を与える可能性があります。たとえば、航空宇宙産業では、燃料効率を向上させ、積載量を増やすために重量の削減が非常に重要です。 さらに、プラスチック製コンポーネントは費用対効果にも優れています。プラスチック部品の製造プロセスは、一般に金属部品の製造プロセスよりも安価です。たとえば、プラスチック射出成形を使用すると、ユニットあたりのコストを低く抑えて大量生産できます。このコスト上の利点は、自動車メーカーなど、大量の部品を必要とする業界にとって特に有益です。 計器用プラスチック部品は、その機能的利点に加えて、持続可能性への取り組みにも貢献します。プラスチックはリサイクルして再利用できるため、廃棄物が削減され、環境への影響が最小限に抑えられます。現在、多くの製造業者が再生プラスチック材料を生産プロセスに組み込んでおり、持続可能性をさらに促進し、二酸化炭素排出量を削減しています。 製品名 OEMプラスチック射出成形部品 テクノロジー 発泡/通常射出/構造発泡成形/オーバーモールド/ガスアシスト射出成形 当社のサービス OEM/ODM ただし、すべてのプラスチックが同じように作られているわけではないことに注意することが重要です。プラスチックの種類が異なれば、さまざまな特性と特性が得られます。メーカーは、強度、耐熱性、化学的適合性などの要素を考慮して、各コンポーネントに適切なプラスチック材料を慎重に選択する必要があります。これにより、最終製品が要求仕様を満たし、意図された用途で最適に動作することが保証されます。 結論として、計器用プラスチック部品はさまざまな業界の製造において重要な役割を果たしています。多用途性、耐久性、軽量性、そしてコスト効率の良さにより、楽器や装置の製造に欠かせないものとなっています。プラスチックコンポーネントには、カスタマイズオプション、過酷な条件への耐性、軽量化など、数多くの利点があります。さらに、リサイクルと再利用を通じて持続可能性への取り組みにも貢献します。ただし、メーカーにとって最適なパフォーマンスを確保するには、各コンポーネントに適切なプラスチック材料を選択することが重要です。多くの利点があるため、計器用プラスチック部品は引き続き製造プロセスの重要な部分であり続けます。

If you’re looking to create a plastic prototype of a functional component, especially for a product or a part that includes a functional aspect such as electronics integration, moving parts, or specific material properties, here are the general steps and considerations involved:Steps to Develop a Plastic Prototype for a Functional Component: 1.Conceptualization and Design: 2.Define…

Proper Cleaning Techniques for Motorcycle Plastic Parts Motorcycles are a popular mode of transportation for many people around the world. They offer a sense of freedom and adventure that is hard to replicate with any other vehicle. However, like any machine, motorcycles require regular maintenance to keep them running smoothly and looking their best. One…

Best Online Retailers for Motorcycle Plastic Parts When it comes to maintaining and customizing your motorcycle, finding the right parts can be crucial. Motorcycle plastic parts, in particular, are essential for both the aesthetics and functionality of your bike. Whether you’re looking to replace a damaged fairing or add a new fender, it’s important to…

Dashboard When you think about the components that make up a car, the dashboard is often one of the first things that come to mind. The dashboard is not only a functional part of the vehicle but also serves as a focal point for the driver, providing important information and controls within easy reach. In…