The Benefits of Working with a Reputable Plastic Automobile Spare Parts Manufacturer

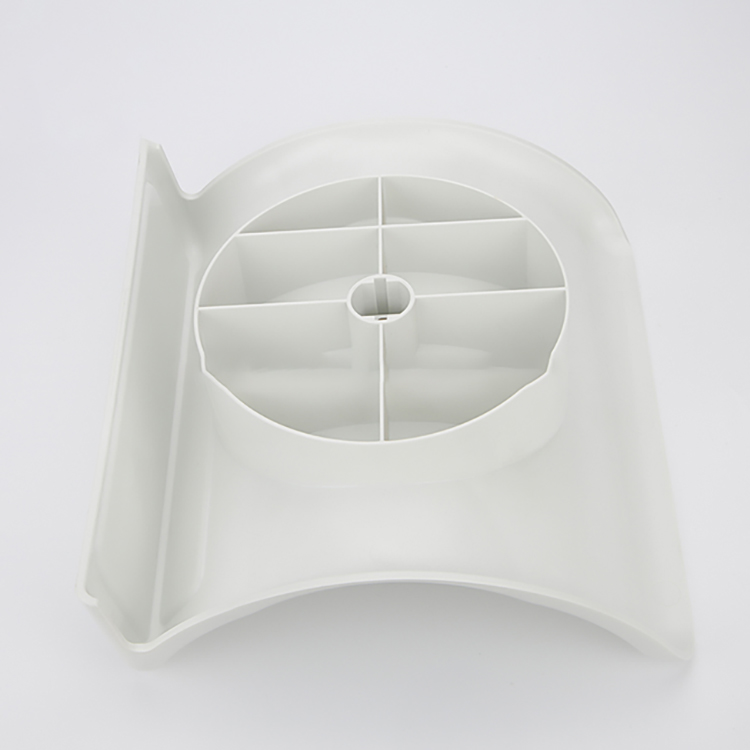

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

| Product Name | OEM Plastic injection molding Parts |

| Quotation | According To Your Drawing(Size / Material / Required Technology / Etc.) |

Rapid prototyping is a crucial process in product development, enabling designers and engineers to quickly iterate and refine their concepts. When it comes to creating aluminum prototypes, precision and speed are key. Here, we explore the most effective methods for producing aluminum prototypes, focusing on rapid and controlled techniques that ensure high-quality outcomes. 1. CNC…

How to Choose the Right Plastic Spare Parts for Your Cool Room The Benefits of Using Plastic Spare Parts in Cool Room Construction

The Benefits of Using Plastic Parts in Manufacturing When it comes to manufacturing, plastic parts are becoming increasingly popular. From automotive to medical, plastic parts are being used in a variety of industries. But why are plastic parts so popular? What are the benefits of using plastic parts in manufacturing? One of the biggest benefits…

The Benefits of Using Plastic Parts in Motorcycle Manufacturing The use of plastic parts in motorcycle manufacturing has revolutionized the industry, offering a range of benefits that make the production process more efficient and cost-effective. From improved performance to increased durability, plastic parts are an essential component of modern motorcycle manufacturing. One of the most…

Producing ABS injection molded plastic parts for low-volume production involves several considerations and steps to ensure quality and cost-effectiveness. Here’s a structured approach: (1).Design Preparation: Start with detailed CAD designs optimized for injection molding. Ensure designs consider draft angles, wall thickness, and part geometry suitable for ABS.(2).Prototype Development: Create prototypes using rapid prototyping methods like…

The Benefits of Using Plastic Gym Parts: Exploring the Advantages of Durable, Cost-Effective Equipment Using plastic gym parts is becoming increasingly popular among gym owners and fitness enthusiasts alike. Plastic gym parts are durable, cost-effective, and easy to maintain, making them an ideal choice for any gym. One of the main benefits of using plastic…