Certainly! In manufacturing and product development, “model” and “prototype” are terms often used to describe different stages and purposes of the development process.

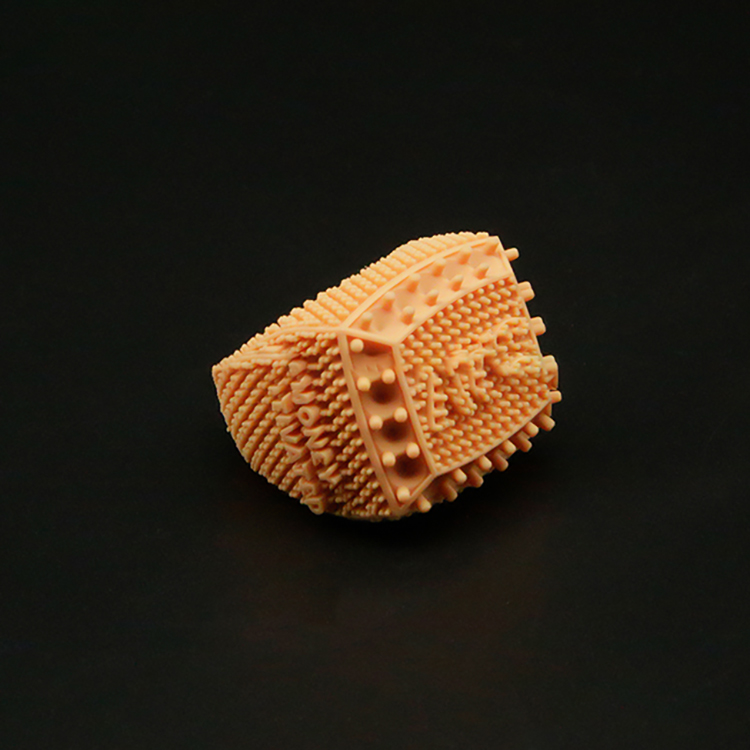

Model:

A model typically refers to a representation of a product or system that may or may not function like the final product. Models are used primarily to visualize and test design concepts, understand proportions, and communicate ideas. They can range from simple mock-ups made of basic materials like cardboard or foam to more detailed representations made using 3D printing or other rapid prototyping methods. Models are often used early in the design phase to validate ideas before investing in more costly prototypes.

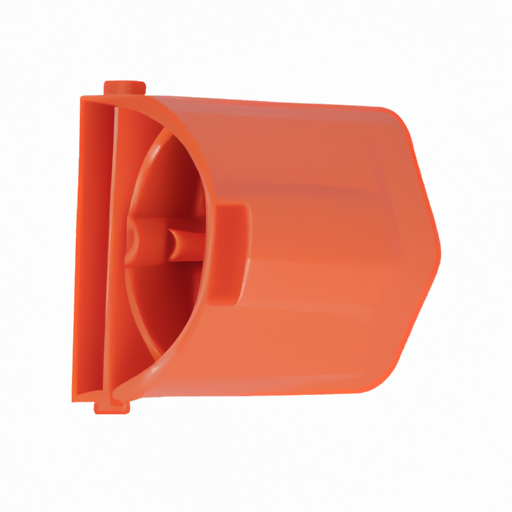

Prototype:

A prototype, on the other hand, is a functional representation of the final product. It is used to test and validate the design, functionality, and performance characteristics of the product. Prototypes are typically closer to the final product in terms of materials, components, and manufacturing methods. They are essential for identifying design flaws, assessing usability, and gathering feedback from stakeholders or potential users. Prototypes can be made using similar manufacturing processes as the final product, such as CNC machining, injection molding, or casting.

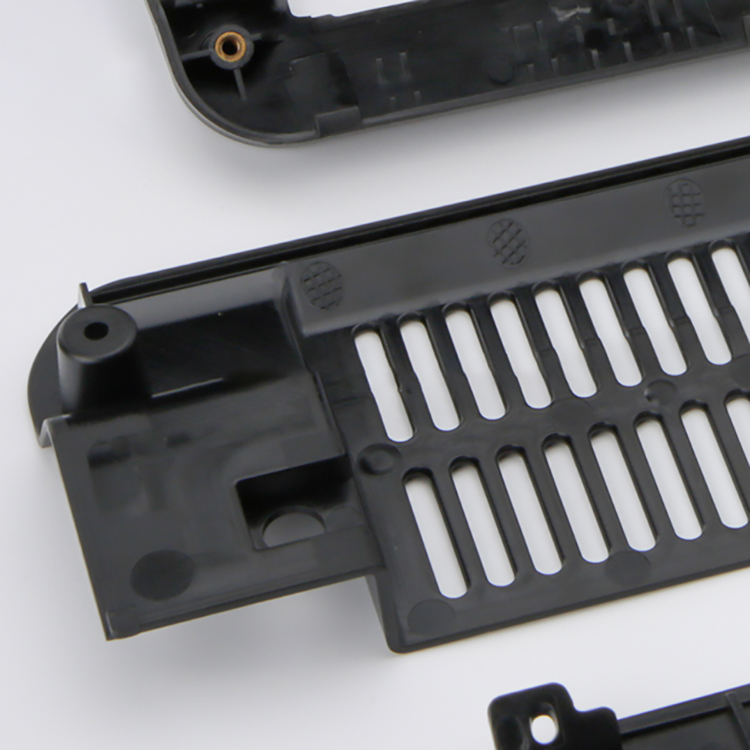

Prototype Tooling:

Prototype tooling refers to the molds, dies, or tooling used to produce prototypes of a product using manufacturing methods like injection molding or casting. Prototype tooling is often designed and built with faster turnaround times and lower costs compared to production tooling, which is used for full-scale manufacturing. It allows designers and engineers to produce small batches of prototypes for testing and validation purposes without the high initial investment required for production tooling.

In summary, while both models and prototypes serve important roles in product development, models are non-functional representations used for visualization and conceptual testing, whereas prototypes are functional representations used for testing and validating design concepts and performance characteristics. Prototype tooling facilitates the production of prototypes using manufacturing processes similar to those used in full-scale production.