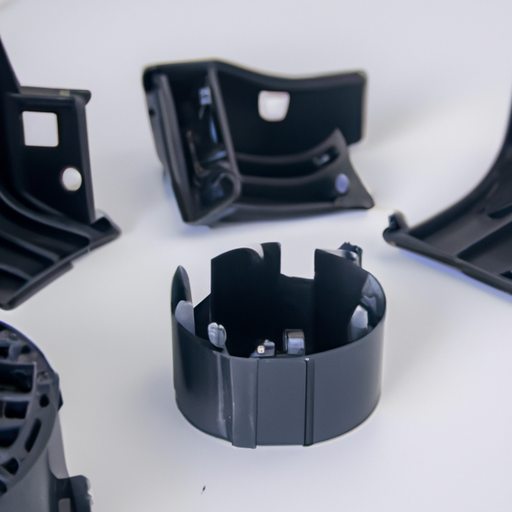

How to Minimize Plastic Part Warpage: Tips and Techniques for Designers and Manufacturers

Are you a designer or manufacturer who is struggling with plastic part warpage? If so, you’re not alone. Warpage is a common issue in the plastic injection molding industry, and it can be a real headache for designers and manufacturers.

Fortunately, there are some tips and techniques you can use to minimize plastic part warpage. In this blog post, we’ll discuss some of the most effective ways to reduce warpage and ensure your parts come out looking great.

1. Design for Warpage

The best way to minimize plastic part warpage is to design for it. This means taking into account the warpage that will occur during the injection molding process and designing your parts accordingly. For example, you can use ribs and gussets to strengthen the part and reduce warpage.

2. Use the Right Resin

The type of resin you use can have a big impact on warpage. Some resins are more prone to warpage than others, so it’s important to choose the right one for your application. You should also consider the wall thickness of the part and the type of molding process you’re using.

3. Optimize the Mold Design

The design of the mold can also affect warpage. If the mold is not designed properly, it can cause uneven cooling and lead to warpage. Make sure the mold is designed with the right features and that it has adequate cooling channels.

4. Control the Process

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

The injection molding process can also affect warpage. Make sure you’re controlling the process parameters, such as temperature, pressure, and cycle time. This will help ensure that the part is molded correctly and that warpage is minimized.

5. Use Support Structures

Support structures, such as pins and bushings, can help reduce warpage. These structures provide additional support to the part and help keep it from warping.

These are just a few tips and techniques you can use to minimize plastic part warpage. By following these tips, you can ensure that your parts come out looking great and that warpage is minimized. Good luck!