The Benefits of Using Plastic Parts Direct in Manufacturing Processes

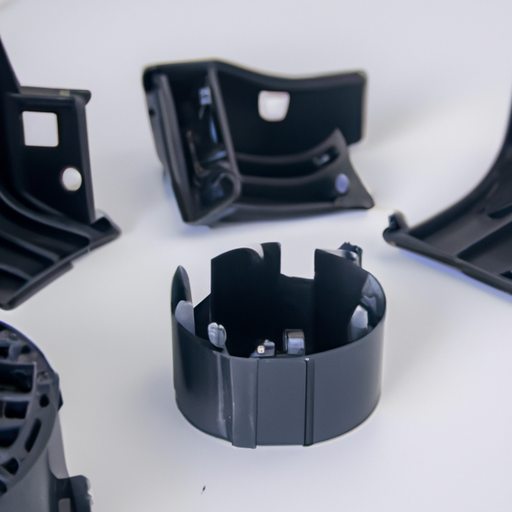

Plastic parts direct is a term that refers to the process of obtaining plastic parts directly from the manufacturer, without the need for intermediaries or middlemen. This method of sourcing plastic parts has gained popularity in recent years due to its numerous benefits for manufacturers. In this article, we will explore the advantages of using plastic parts direct in manufacturing processes.

One of the primary benefits of using plastic parts direct is cost savings. By eliminating intermediaries, manufacturers can negotiate directly with the plastic parts manufacturer, resulting in lower prices. This cost reduction can be significant, especially when ordering large quantities of plastic parts. Additionally, manufacturers can avoid additional fees and markups that are typically associated with middlemen, further reducing costs.

Another advantage of using plastic parts direct is increased control over the manufacturing process. When working with intermediaries, manufacturers often have limited visibility and control over the production timeline and quality of the plastic parts. However, by sourcing directly from the manufacturer, manufacturers can have a more hands-on approach, ensuring that the plastic parts meet their specific requirements and standards. This increased control can lead to improved product quality and customer satisfaction.

Furthermore, using plastic parts direct allows for faster turnaround times. When working with intermediaries, manufacturers may experience delays due to communication issues or logistical challenges. However, by dealing directly with the manufacturer, manufacturers can streamline the ordering and production process, resulting in shorter lead times. This can be particularly beneficial for manufacturers who operate in industries with fast-paced production cycles or have tight deadlines to meet.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

In addition to cost savings, increased control, and faster turnaround times, using plastic parts direct also offers manufacturers greater flexibility. When working with intermediaries, manufacturers may be limited in terms of customization options or the ability to make changes to the design or specifications of the plastic parts. However, by sourcing directly from the manufacturer, manufacturers can have more flexibility in terms of customization and modifications. This can be particularly advantageous for manufacturers who require unique or specialized plastic parts for their products.

Moreover, using plastic parts direct can also result in improved communication and collaboration between manufacturers and the plastic parts manufacturer. By establishing a direct relationship, manufacturers can easily communicate their requirements, provide feedback, and address any concerns or issues that may arise during the production process. This open line of communication can lead to a more efficient and productive partnership, ultimately benefiting both parties involved.

In conclusion, using plastic parts direct in manufacturing processes offers numerous benefits for manufacturers. From cost savings and increased control to faster turnaround times and greater flexibility, this sourcing method can significantly enhance the overall manufacturing experience. By eliminating intermediaries and establishing a direct relationship with the plastic parts manufacturer, manufacturers can optimize their production processes, improve product quality, and ultimately, achieve greater success in their respective industries.