Table of Contents

Benefits of Using Sai Precision Tools for Plastic Injection Moulds

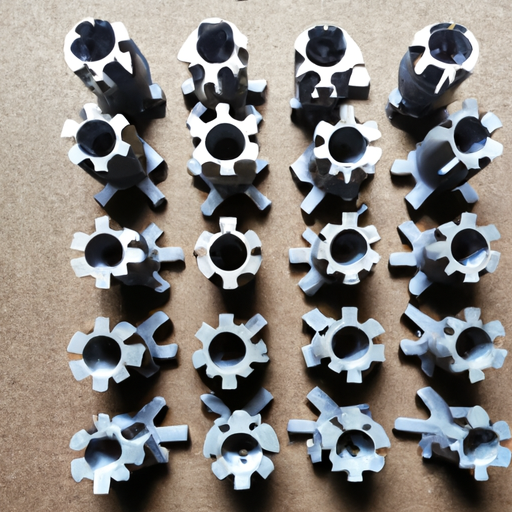

Plastic injection moulds play a crucial role in the manufacturing industry, especially in the production of industrial plastic components. These moulds are used to create intricate shapes and designs with precision and accuracy. When it comes to choosing a reliable and reputable manufacturer for plastic injection moulds, Sai Precision Tools stands out as a top choice.

Sai Precision Tools is a leading manufacturer of plastic injection moulds and industrial plastic components. With years of experience and expertise in the field, they have established themselves as a trusted name in the industry. One of the key benefits of using Sai Precision Tools for plastic injection moulds is their commitment to quality and precision.

Quality is paramount when it comes to plastic injection moulds, as even the slightest imperfection can result in defective products. Sai Precision Tools understands this and ensures that each mould they produce meets the highest standards of quality. Their team of skilled engineers and technicians use state-of-the-art technology and equipment to design and manufacture moulds that are precise and reliable.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

In addition to quality, Sai Precision Tools also offers a wide range of customization options for their plastic injection moulds. They work closely with their clients to understand their specific requirements and tailor the moulds to meet their exact specifications. This level of customization ensures that the final products are of the highest quality and meet the unique needs of each client.

Another benefit of using Sai Precision Tools for plastic injection moulds is their quick turnaround time. In the manufacturing industry, time is of the essence, and delays can be costly. Sai Precision Tools understands this and strives to deliver their products in a timely manner. Their efficient production process and streamlined operations allow them to meet tight deadlines without compromising on quality.

Furthermore, Sai Precision Tools offers competitive pricing for their plastic injection moulds. While quality and precision are their top priorities, they also understand the importance of cost-effectiveness. By optimizing their production process and sourcing materials efficiently, they are able to offer competitive prices without sacrificing quality.

When it comes to customer service, Sai Precision Tools excels in providing exceptional support and assistance to their clients. Their team of knowledgeable professionals is always available to answer any questions and address any concerns that may arise. They are committed to building long-lasting relationships with their clients and ensuring their satisfaction with every product they deliver.

In conclusion, Sai Precision Tools is a reliable and reputable manufacturer of plastic injection moulds and industrial plastic components. Their commitment to quality, precision, customization, quick turnaround time, competitive pricing, and exceptional customer service set them apart from their competitors. If you are in need of high-quality plastic injection moulds, Sai Precision Tools is the perfect choice for all your manufacturing needs.

How Sai Precision Tools Ensures Quality in Manufacturing Industrial Plastic Components

Sai Precision Tools is a leading manufacturer of plastic injection moulds and industrial plastic components. With a strong focus on quality and precision, the company has established itself as a trusted partner for businesses in various industries. In this article, we will explore how Sai Precision Tools ensures quality in manufacturing industrial plastic components.

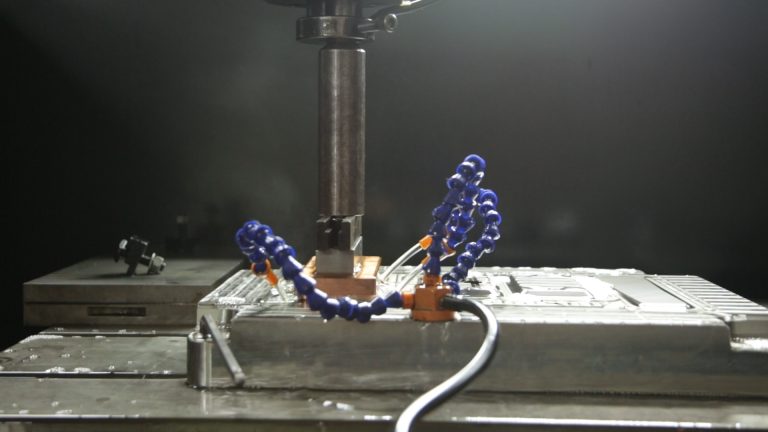

One of the key factors that sets Sai Precision Tools apart from its competitors is its commitment to using the latest technology and machinery in its manufacturing processes. The company invests heavily in state-of-the-art equipment to ensure that its products meet the highest standards of quality and precision. By leveraging cutting-edge technology, Sai Precision Tools is able to produce industrial plastic components that are not only durable and reliable but also highly efficient.

In addition to using advanced technology, Sai Precision Tools also places a strong emphasis on quality control throughout the manufacturing process. The company has implemented strict quality control measures at every stage of production, from design and prototyping to final inspection and testing. By closely monitoring each step of the manufacturing process, Sai Precision Tools is able to identify and address any potential issues before they can impact the quality of the final product.

Furthermore, Sai Precision Tools works closely with its clients to understand their specific requirements and expectations. The company’s team of experienced engineers and designers collaborate with clients to develop custom solutions that meet their unique needs. By taking a customer-centric approach to manufacturing, Sai Precision Tools is able to deliver industrial plastic components that not only meet but exceed the expectations of its clients.

Another key aspect of Sai Precision Tools’ quality assurance process is its rigorous testing and validation procedures. Before any product is released to the market, it undergoes a series of comprehensive tests to ensure that it meets the company’s strict quality standards. By conducting thorough testing and validation, Sai Precision Tools is able to guarantee the reliability and performance of its industrial plastic components.

Moreover, Sai Precision Tools is committed to continuous improvement and innovation in its manufacturing processes. The company regularly invests in research and development to explore new materials, technologies, and techniques that can further enhance the quality of its products. By staying at the forefront of industry trends and advancements, Sai Precision Tools is able to deliver cutting-edge solutions to its clients.

In conclusion, Sai Precision Tools is a trusted manufacturer of industrial plastic components that prioritizes quality and precision in its manufacturing processes. By leveraging advanced technology, implementing strict quality control measures, collaborating with clients, conducting rigorous testing and validation, and investing in research and development, the company ensures that its products meet the highest standards of quality and reliability. With a commitment to excellence and innovation, Sai Precision Tools continues to be a preferred partner for businesses in need of high-quality industrial plastic components.