The Benefits of ABS PP PC PA66 Plastic Injection Parts in Manufacturing

Plastic injection parts have become an integral part of the manufacturing industry. They are widely used in various sectors, including automotive, electronics, and consumer goods. Among the different types of plastic injection parts, ABS PP PC PA66 stands out as a popular choice. These materials offer a range of benefits that make them ideal for manufacturing applications.

One of the key advantages of ABS PP PC PA66 plastic injection parts is their durability. These materials are known for their high strength and resistance to impact. This makes them suitable for applications that require components to withstand heavy loads or harsh environments. For example, in the automotive industry, ABS PP PC PA66 parts are commonly used in the production of bumpers, dashboards, and interior trims. Their ability to withstand impacts and vibrations ensures the safety and longevity of these components.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

In addition to their durability, ABS PP PC PA66 plastic injection parts also offer excellent chemical resistance. They can withstand exposure to a wide range of chemicals, including oils, solvents, and acids. This makes them suitable for applications in industries such as chemical processing, where components may come into contact with corrosive substances. The chemical resistance of ABS PP PC PA66 parts ensures their longevity and reliability in such demanding environments.

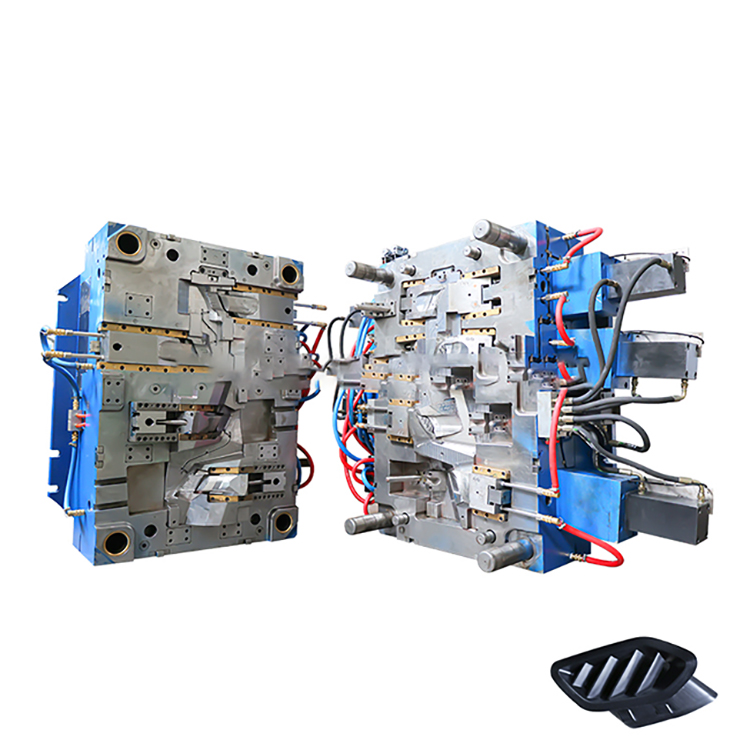

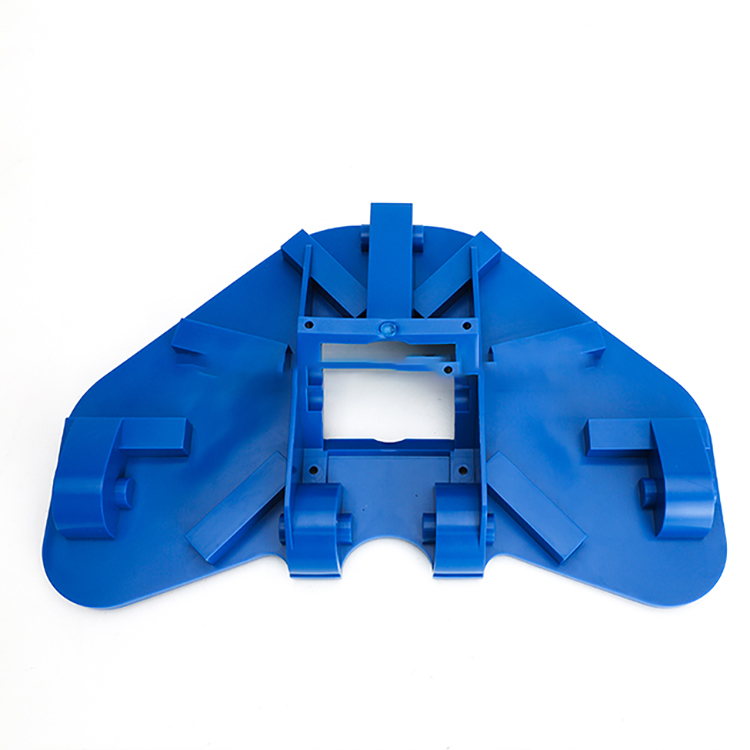

Another benefit of ABS PP PC PA66 plastic injection parts is their versatility. These materials can be easily molded into complex shapes and designs, allowing manufacturers to create customized components for specific applications. This flexibility in design makes ABS PP PC PA66 parts suitable for a wide range of products, from small electronic devices to large industrial machinery. Manufacturers can easily incorporate features such as threads, undercuts, and inserts into the design of these parts, further enhancing their functionality.

Furthermore, ABS PP PC PA66 plastic injection parts offer excellent dimensional stability. They have low shrinkage rates, which means that the parts retain their shape and size even after the molding process. This is crucial in manufacturing applications where precision and accuracy are essential. The dimensional stability of ABS PP PC PA66 parts ensures that they fit perfectly into assemblies and maintain their functionality over time.

Additionally, ABS PP PC PA66 plastic injection parts have good electrical insulation properties. They are non-conductive materials, which makes them suitable for applications that require electrical insulation. For example, in the electronics industry, ABS PP PC PA66 parts are commonly used in the production of connectors, housings, and insulators. Their electrical insulation properties ensure the safety and reliability of electronic devices.

In conclusion, ABS PP PC PA66 plastic injection parts offer a range of benefits that make them ideal for manufacturing applications. Their durability, chemical resistance, versatility, dimensional stability, and electrical insulation properties make them suitable for a wide range of industries. Whether it is in the automotive, electronics, or consumer goods sector, ABS PP PC PA66 parts provide manufacturers with reliable and high-quality components. With their excellent performance and design flexibility, ABS PP PC PA66 plastic injection parts continue to play a crucial role in the manufacturing industry.