The Advantages of Using Plastic Auto Parts

Plastic auto parts have become increasingly popular in the automotive industry due to their numerous advantages. From improved fuel efficiency to enhanced safety features, plastic auto parts offer a range of benefits that make them a preferred choice for manufacturers and consumers alike.

One of the primary advantages of using plastic auto parts is their lightweight nature. Compared to traditional metal parts, plastic components are significantly lighter, which can contribute to improved fuel efficiency. By reducing the overall weight of the vehicle, plastic parts help to decrease the amount of energy required to propel the car, resulting in better mileage and reduced emissions. This not only benefits the environment but also saves consumers money at the pump.

In addition to their lightweight nature, plastic auto parts offer excellent durability. Modern plastics are engineered to withstand extreme temperatures, harsh weather conditions, and the wear and tear of everyday use. Unlike metal parts, plastic components are less prone to rust and corrosion, making them a more long-lasting option. This durability translates into lower maintenance costs for vehicle owners, as plastic parts are less likely to require frequent repairs or replacements.

Furthermore, plastic auto parts provide enhanced safety features. Manufacturers can design plastic components with specific properties that improve crash resistance and occupant protection. For instance, plastic bumpers are designed to absorb impact energy during a collision, reducing the force transferred to the vehicle’s occupants. Additionally, plastic airbags are lighter and more flexible than their metal counterparts, allowing for better deployment and cushioning in the event of an accident. These safety features contribute to a higher level of protection for drivers and passengers, making plastic auto parts an essential aspect of vehicle safety.

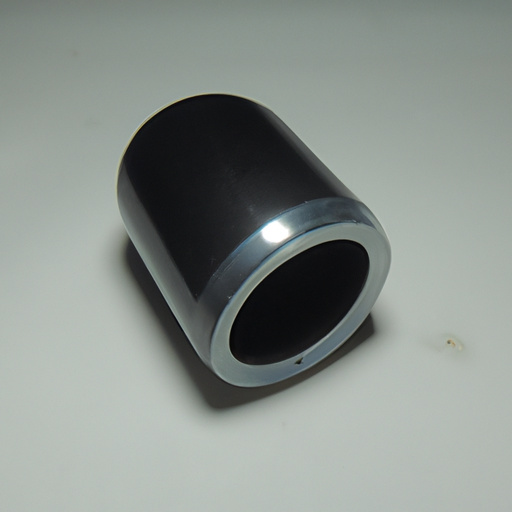

Another advantage of plastic auto parts is their versatility in design. Plastic components can be molded into various shapes and sizes, allowing for greater flexibility in design and aesthetics. This versatility enables manufacturers to create sleek and aerodynamic vehicle designs that not only enhance the overall appearance but also improve aerodynamic performance. Additionally, plastic parts can be easily colored, eliminating the need for additional painting processes and reducing production costs. This flexibility in design and customization options makes plastic auto parts an attractive choice for both manufacturers and consumers.

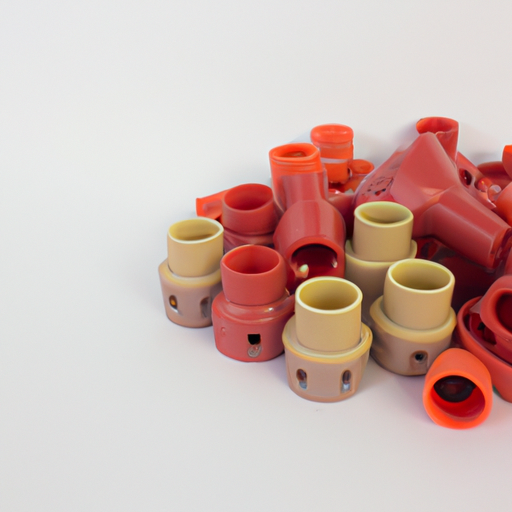

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

Moreover, plastic auto parts offer cost advantages. Plastic components are generally less expensive to produce than their metal counterparts, making them a cost-effective option for manufacturers. The lower production costs can be passed on to consumers, resulting in more affordable vehicles. Additionally, plastic parts are easier to assemble and install, reducing labor costs during the manufacturing process. These cost advantages make plastic auto parts a viable option for manufacturers looking to optimize production efficiency and reduce overall expenses.

In conclusion, plastic auto parts offer numerous advantages that make them a preferred choice in the automotive industry. Their lightweight nature contributes to improved fuel efficiency, while their durability ensures long-lasting performance. Plastic components also provide enhanced safety features and offer versatility in design. Furthermore, plastic auto parts offer cost advantages, making them an attractive option for manufacturers and consumers alike. With these advantages in mind, it is clear why plastic auto parts have gained popularity and continue to play a significant role in the automotive industry.