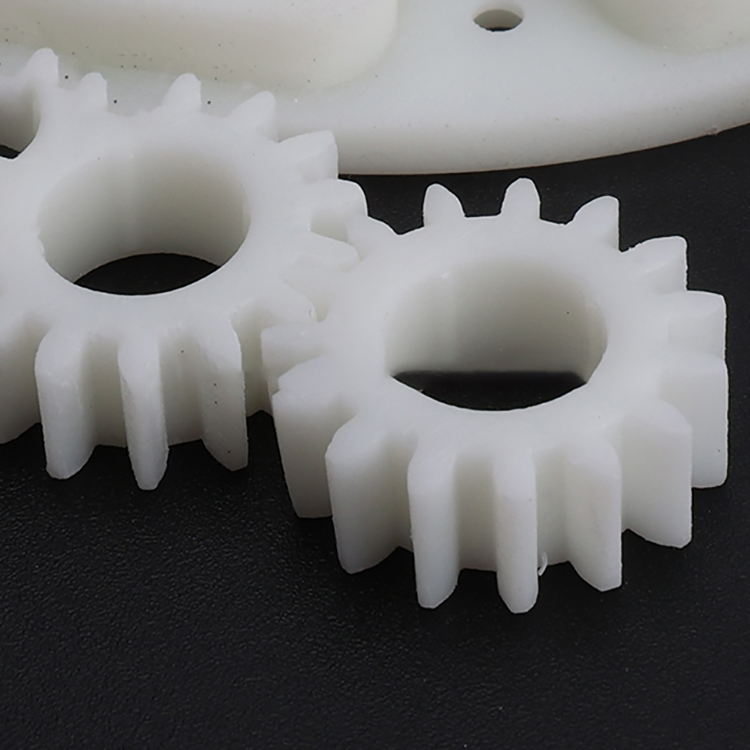

The Basics of Molding Small Plastic Parts

Molding small plastic parts is a fundamental process in the manufacturing industry. It involves shaping molten plastic into a desired form using a mold. This article will provide an overview of the basics of molding small plastic parts, including the different types of molding processes, the materials used, and the steps involved.

There are several types of molding processes commonly used for small plastic parts. Injection molding is the most widely used method, where molten plastic is injected into a mold cavity under high pressure. This process allows for complex shapes and precise dimensions. Another common method is blow molding, which is used for hollow parts such as bottles. In blow molding, a tube of molten plastic is inflated to take the shape of the mold. Other methods include compression molding, rotational molding, and extrusion molding.

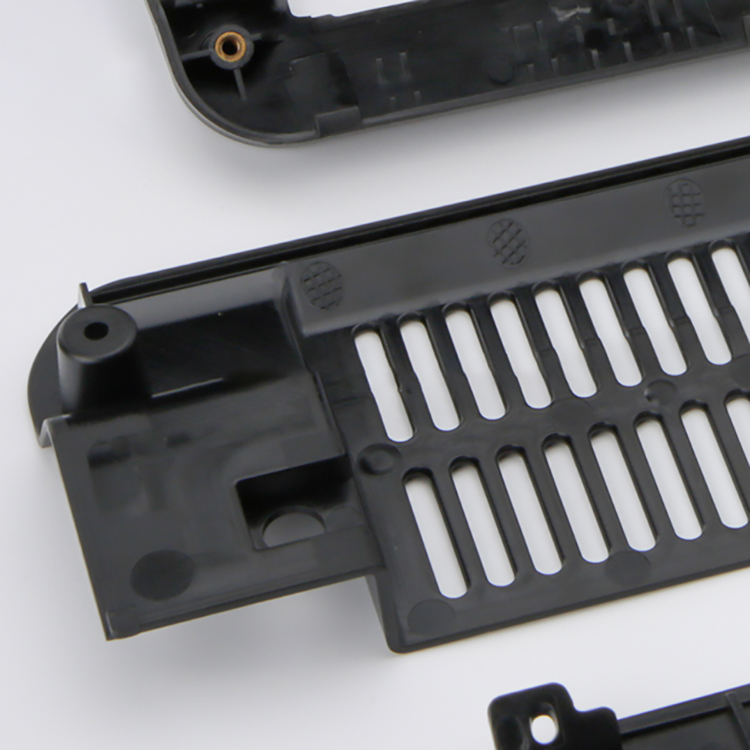

The choice of molding process depends on factors such as the complexity of the part, the desired quantity, and the material being used. Speaking of materials, there is a wide range of plastics that can be used for molding small parts. Common materials include polyethylene, polypropylene, polystyrene, and polyvinyl chloride (PVC). Each material has its own unique properties, such as flexibility, durability, and heat resistance, which make them suitable for different applications.

The process of molding small plastic parts typically involves several steps. First, the mold is prepared by creating a cavity that matches the desired shape of the part. This can be done by machining the mold out of metal or by using a pre-made mold. Once the mold is ready, the plastic material is heated to a molten state and injected or blown into the mold cavity. The mold is then cooled to solidify the plastic, and the part is ejected from the mold.

To ensure the quality of the molded parts, several factors need to be considered. One important factor is the design of the mold. The mold should have proper venting and cooling channels to allow for efficient filling and cooling of the plastic. Additionally, the mold should be made from a material that can withstand the high temperatures and pressures involved in the molding process.

Another factor to consider is the control of process parameters. The temperature, pressure, and cooling time need to be carefully controlled to achieve the desired part quality. This can be done through the use of advanced molding machines that allow for precise control of these parameters.

In conclusion, molding small plastic parts is a crucial process in the manufacturing industry. It involves shaping molten plastic into a desired form using a mold. There are various types of molding processes and materials that can be used, depending on the complexity and quantity of the parts. The process involves several steps, including mold preparation, plastic injection or blowing, cooling, and part ejection. To ensure high-quality parts, proper mold design and control of process parameters are essential. By understanding the basics of molding small plastic parts, manufacturers can produce high-quality products efficiently and effectively.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |