Understanding the Key Components of Plastic Injection Molds

Plastic injection molds are essential tools in the manufacturing industry. They are used to produce a wide range of plastic products, from simple household items to complex automotive parts. Understanding the key components of plastic injection molds is crucial for anyone involved in the design and production of plastic products.

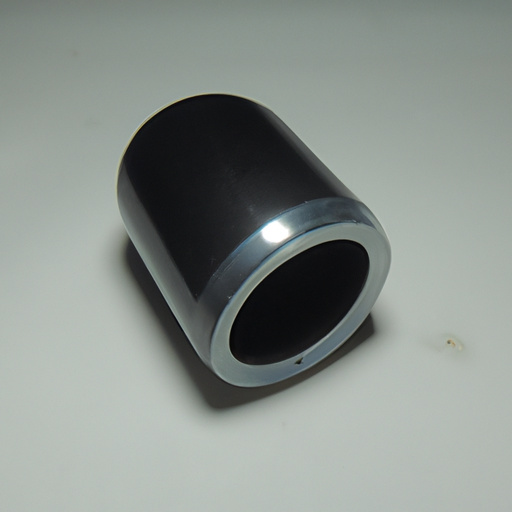

One of the most important components of a plastic injection mold is the cavity. The cavity is the part of the mold that shapes the plastic material into the desired product. It is typically made of hardened steel or aluminum and is designed to withstand the high pressures and temperatures involved in the injection molding process. The cavity is carefully machined to ensure that the final product has the desired dimensions and surface finish.

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Our Services | OEM/ODM |

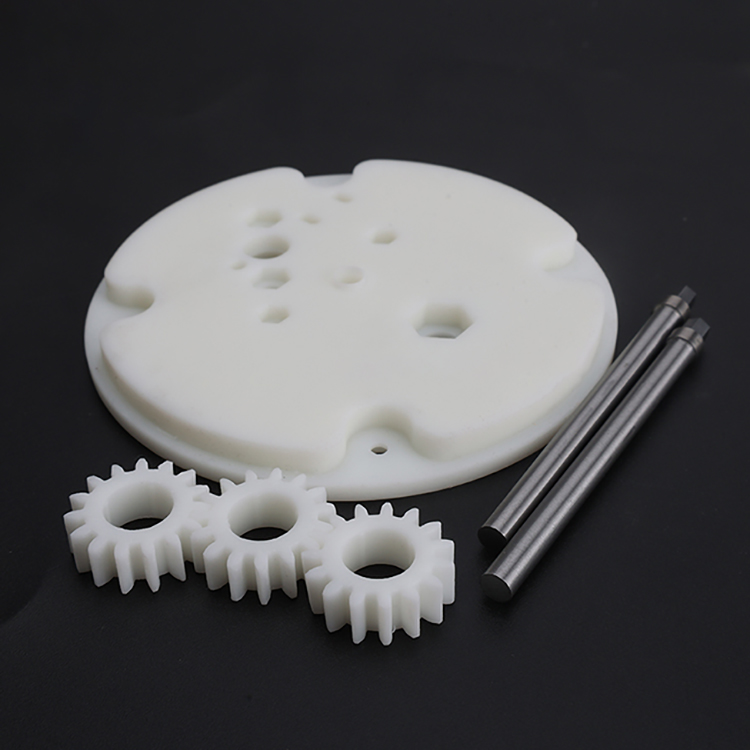

Another key component of a plastic injection mold is the core. The core is the part of the mold that creates the internal features of the product. It is usually located inside the cavity and is designed to move or rotate to release the molded part. Like the cavity, the core is made of hardened steel or aluminum and is precision machined to ensure accurate and consistent results.

In addition to the cavity and core, plastic injection molds also include other components that are essential for the molding process. One such component is the sprue. The sprue is the channel through which the molten plastic material is injected into the mold. It is typically located at the edge of the mold and is designed to allow for easy filling of the cavity. The sprue is often connected to a runner system, which distributes the plastic material to multiple cavities in a multi-cavity mold.

Another important component of a plastic injection mold is the ejector system. The ejector system is responsible for pushing the molded part out of the mold once it has cooled and solidified. It typically consists of ejector pins or plates that are activated by hydraulic or mechanical means. The ejector system is designed to ensure that the molded part is released from the mold without any damage or distortion.

Other components of a plastic injection mold include cooling channels, which help to control the temperature of the mold during the molding process, and venting systems, which allow for the escape of air and gases from the mold. These components are crucial for achieving high-quality and defect-free plastic products.

In conclusion, understanding the key components of plastic injection molds is essential for anyone involved in the design and production of plastic products. The cavity and core are the main components that shape the plastic material into the desired product, while the sprue, runner system, and ejector system are responsible for the injection, distribution, and ejection of the plastic material. Cooling channels and venting systems are also important for achieving high-quality results. By understanding these components and their functions, manufacturers can ensure the production of high-quality plastic products that meet the desired specifications.