Understanding the Key Components of Plastic Molding Machine Parts

Plastic molding machines are widely used in various industries for the production of plastic products. These machines consist of several key components that work together to ensure the smooth and efficient operation of the machine. Understanding these components is essential for anyone working with or operating plastic molding machines.

One of the most important components of a plastic molding machine is the injection unit. This unit is responsible for melting and injecting the plastic material into the mold. It consists of a hopper, a barrel, and a screw. The hopper is where the plastic material is loaded, and it feeds the material into the barrel. The barrel is heated to melt the plastic, and the screw pushes the molten plastic into the mold.

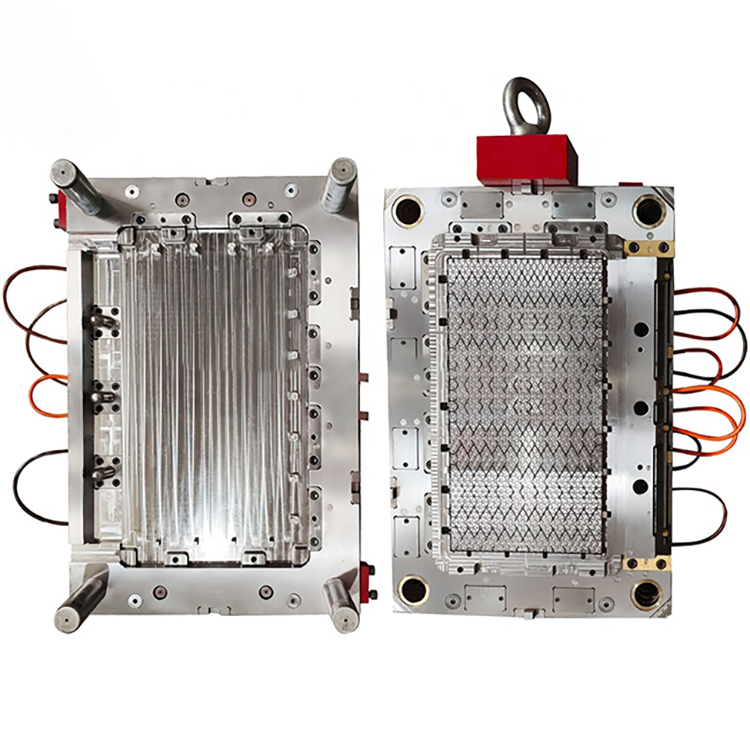

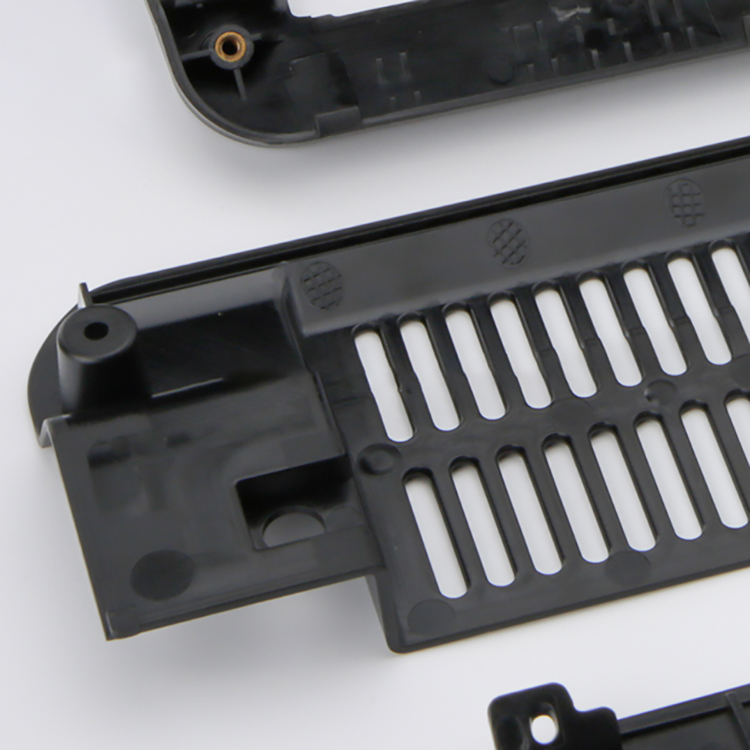

The mold is another crucial component of a plastic molding machine. It is a hollow cavity that gives shape to the plastic material. The mold is made of two halves, the core, and the cavity. These halves are precision-machined to create the desired shape of the final product. The mold also includes channels and gates through which the molten plastic flows.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

To ensure the proper functioning of the mold, it needs to be cooled. This is where the cooling system comes into play. The cooling system consists of water channels that circulate cold water around the mold to cool it down. Cooling is essential to solidify the plastic material and allow for easy ejection of the finished product from the mold.

The clamping unit is responsible for holding the mold in place during the injection process. It consists of a clamping mechanism, which applies pressure to keep the mold closed, and a hydraulic system, which provides the necessary force for clamping. The clamping unit ensures that the mold remains securely closed during the injection and cooling phases.

Another important component of a plastic molding machine is the control system. This system is responsible for monitoring and controlling various parameters of the machine, such as temperature, pressure, and timing. It ensures that the machine operates within the desired parameters and produces high-quality plastic products. The control system also includes safety features to prevent accidents and protect the operator.

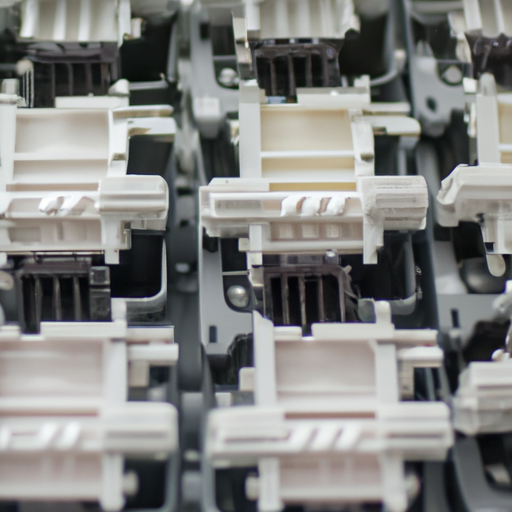

In addition to these key components, plastic molding machines may also have auxiliary equipment. This equipment includes material handling systems, such as conveyors and robots, which automate the loading and unloading of plastic materials. It may also include granulators, which grind up scrap plastic for recycling, and mold temperature controllers, which regulate the temperature of the mold.

Understanding the key components of plastic molding machine parts is essential for anyone involved in the plastic molding industry. It allows for better troubleshooting and maintenance of the machines, leading to improved productivity and product quality. By knowing how each component works and interacts with others, operators can optimize the performance of the machine and ensure its longevity.

In conclusion, plastic molding machines consist of several key components that work together to produce high-quality plastic products. These components include the injection unit, mold, cooling system, clamping unit, and control system. Understanding how each component functions is crucial for the efficient operation of the machine and the production of consistent and reliable plastic products.