How to Use a Plastic Part Cost Estimator Excel Template

Plastic part cost estimation is a crucial aspect of any manufacturing process. Accurately estimating the cost of plastic parts helps businesses make informed decisions about pricing, budgeting, and profitability. One effective tool that can assist in this process is a plastic part cost estimator Excel template. This article will guide you through the steps of using such a template to estimate the cost of plastic parts.

To begin, it is important to understand the purpose of a plastic part cost estimator Excel template. This tool is designed to simplify the process of calculating the cost of manufacturing plastic parts. It provides a structured framework for inputting relevant data and automatically generates cost estimates based on predefined formulas and calculations.

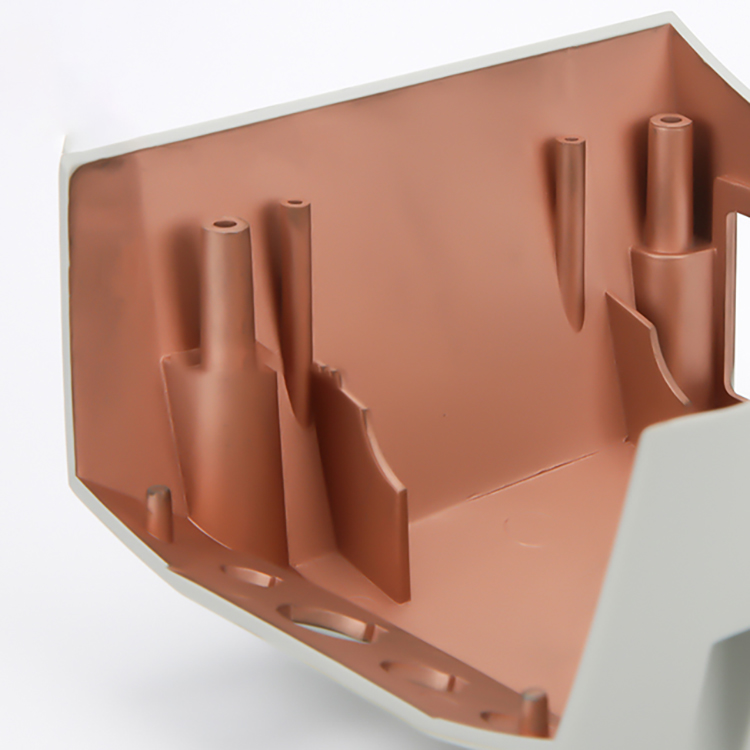

The first step in using a plastic part cost estimator Excel template is to gather all the necessary information. This includes details about the plastic part, such as its dimensions, weight, material type, and any additional features or requirements. Additionally, you will need information about the manufacturing process, such as the hourly rate of labor, machine costs, and overhead expenses.

Once you have gathered all the required information, you can start inputting it into the plastic part cost estimator Excel template. The template will typically have designated cells or sections where you can enter the relevant data. It is important to ensure that you input the information accurately to obtain accurate cost estimates.

After inputting the necessary data, the template will automatically calculate the cost of manufacturing the plastic part. This includes the cost of materials, labor, machine usage, and any additional expenses. The template may also provide a breakdown of these costs, allowing you to identify the major cost drivers and make adjustments if necessary.

It is important to note that a plastic part cost estimator Excel template is a tool that provides estimates based on predefined formulas and calculations. While it can provide a good starting point for cost estimation, it is not a substitute for a comprehensive cost analysis. Factors such as market conditions, supplier pricing, and economies of scale may impact the actual cost of manufacturing a plastic part.

| Delivery | PE bag + paper card/paper skin + export-grade carton / crate / Pallet |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

Once you have obtained the cost estimate from the plastic part cost estimator Excel template, you can use this information to make informed decisions. For example, you can compare the estimated cost with your target price to determine if the project is financially viable. You can also use the cost estimate to negotiate with suppliers or identify areas where cost savings can be achieved.

In conclusion, a plastic part cost estimator Excel template is a valuable tool for estimating the cost of manufacturing plastic parts. By gathering the necessary information and inputting it into the template, you can obtain accurate cost estimates that can guide your decision-making process. However, it is important to remember that the template provides estimates based on predefined formulas and calculations, and other factors may impact the actual cost of manufacturing. Therefore, it is advisable to use the cost estimate as a starting point and conduct a comprehensive cost analysis for a more accurate assessment.