Advantages of ABS Plastic Car Parts

ABS Plastic Car Parts: The Advantages of Choosing this Material

When it comes to manufacturing car parts, choosing the right material is crucial. One material that has gained popularity in recent years is ABS plastic. ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its durability and versatility. In this article, we will explore the advantages of using ABS plastic for car parts.

First and foremost, ABS plastic is incredibly strong and impact-resistant. This makes it an ideal choice for car parts that are exposed to constant wear and tear, such as bumpers and exterior trim. Unlike other materials, ABS plastic can withstand high levels of force without cracking or breaking. This not only ensures the longevity of the car parts but also enhances the overall safety of the vehicle.

Another advantage of ABS plastic car parts is their lightweight nature. Compared to traditional materials like metal, ABS plastic is significantly lighter. This weight reduction has several benefits. Firstly, it improves fuel efficiency by reducing the overall weight of the vehicle. Lighter car parts also contribute to better handling and maneuverability, making the driving experience more enjoyable for the driver.

Furthermore, ABS plastic is highly resistant to chemicals and corrosion. This is particularly important for car parts that are exposed to harsh weather conditions or chemicals on the road. ABS plastic car parts can withstand exposure to salt, oil, and other corrosive substances without deteriorating. This resistance to corrosion ensures that the car parts remain in good condition for a longer period, reducing the need for frequent replacements.

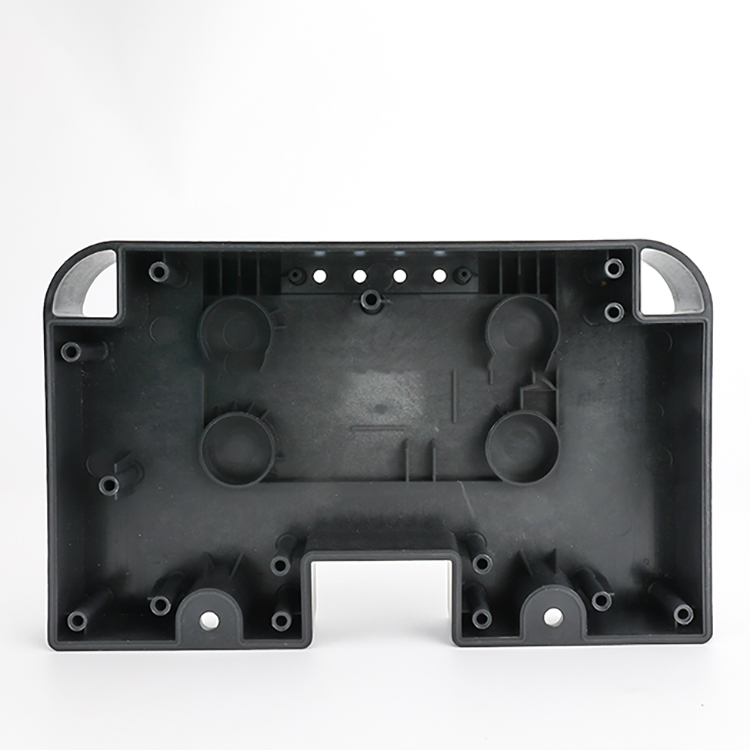

In addition to its physical properties, ABS plastic is also known for its ease of processing. It can be molded into various shapes and sizes, allowing for greater design flexibility. This means that car manufacturers can create intricate and aesthetically pleasing car parts using ABS plastic. Whether it’s a sleek bumper or a stylish interior trim, ABS plastic can be molded to meet the desired specifications.

Moreover, ABS plastic car parts are cost-effective. Compared to other materials like metal or carbon fiber, ABS plastic is relatively inexpensive. This makes it an attractive option for car manufacturers looking to reduce production costs without compromising on quality. Additionally, the ease of processing ABS plastic further contributes to cost savings, as it requires less time and energy to manufacture car parts.

Lastly, ABS plastic is a sustainable choice for car parts. It is a recyclable material, meaning that it can be melted down and reused to create new products. This reduces the environmental impact of manufacturing car parts and promotes a circular economy. By choosing ABS plastic car parts, car manufacturers can contribute to a more sustainable and eco-friendly automotive industry.

In conclusion, ABS plastic car parts offer numerous advantages over traditional materials. Their strength, lightweight nature, resistance to chemicals and corrosion, ease of processing, cost-effectiveness, and sustainability make them an excellent choice for car manufacturers. By opting for ABS plastic car parts, not only can car manufacturers enhance the durability and safety of their vehicles, but they can also contribute to a more efficient and sustainable automotive industry.

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Our Services | OEM/ODM |