Understanding the Importance of Adhesion Mechanisms in Automotive Plastic Parts

Adhesion mechanisms play a crucial role in the performance and durability of automotive plastic parts. These mechanisms are responsible for ensuring that various components of a vehicle remain securely bonded together, even under harsh conditions such as extreme temperatures, vibrations, and exposure to chemicals. Understanding the importance of adhesion mechanisms in automotive plastic parts is essential for manufacturers, engineers, and consumers alike.

One of the primary reasons why adhesion mechanisms are critical in automotive plastic parts is because they help prevent delamination or separation of different components. Delamination can occur when the bond between two materials weakens, leading to a loss of structural integrity and potentially compromising the safety and performance of the vehicle. By ensuring strong adhesion between plastic parts, manufacturers can minimize the risk of delamination and ensure that the vehicle remains structurally sound.

In addition to preventing delamination, adhesion mechanisms also play a key role in enhancing the overall performance of automotive plastic parts. Strong adhesion can improve the mechanical properties of plastic components, such as their tensile strength, impact resistance, and fatigue life. This, in turn, can help extend the lifespan of the vehicle and reduce the likelihood of premature failure or breakdown.

Furthermore, adhesion mechanisms are essential for maintaining the aesthetic appeal of automotive plastic parts. Proper adhesion ensures that painted or coated surfaces remain smooth, uniform, and free from defects such as blistering, cracking, or peeling. This is particularly important for exterior components of a vehicle, as they are exposed to environmental factors such as UV radiation, moisture, and pollutants that can degrade the appearance of the plastic parts over time.

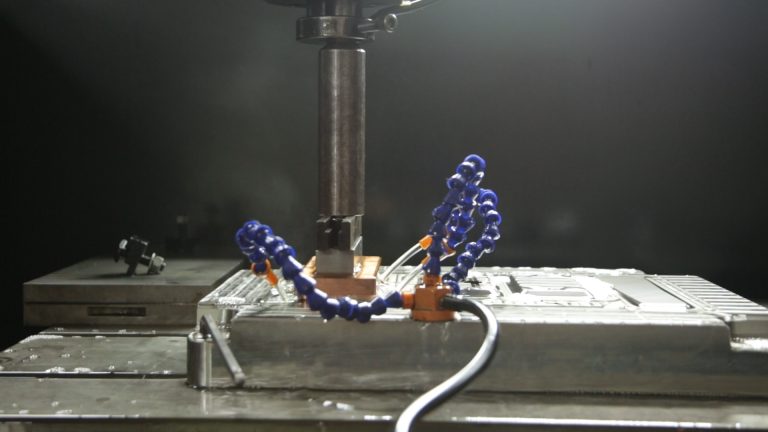

There are several different adhesion mechanisms that can be used to bond automotive plastic parts together. One common method is mechanical adhesion, which involves creating a rough surface texture on the plastic parts to increase the surface area available for bonding. This can be achieved through techniques such as sandblasting, etching, or plasma treatment.

Another popular adhesion mechanism is chemical adhesion, which involves using adhesives or bonding agents to create a strong bond between plastic parts. These adhesives can be tailored to specific materials and applications, ensuring optimal adhesion strength and durability. Additionally, chemical adhesion can be enhanced through the use of primers or surface treatments that promote bonding between the adhesive and the plastic substrate.

In some cases, a combination of mechanical and chemical adhesion mechanisms may be used to achieve the desired bond strength and durability for automotive plastic parts. This hybrid approach can offer the benefits of both methods while mitigating their respective limitations. By understanding the different adhesion mechanisms available and selecting the most appropriate one for a given application, manufacturers can ensure that their automotive plastic parts meet the required performance, safety, and aesthetic standards.

In conclusion, adhesion mechanisms are essential for ensuring the performance, durability, and aesthetic appeal of automotive plastic parts. By understanding the importance of adhesion mechanisms and selecting the most appropriate bonding method for a given application, manufacturers can create high-quality plastic components that meet the stringent requirements of the automotive industry. Strong adhesion not only enhances the structural integrity and mechanical properties of plastic parts but also helps maintain their appearance and extend their lifespan. As automotive technology continues to evolve, the role of adhesion mechanisms in plastic parts will only become more critical in ensuring the safety, reliability, and performance of vehicles on the road.

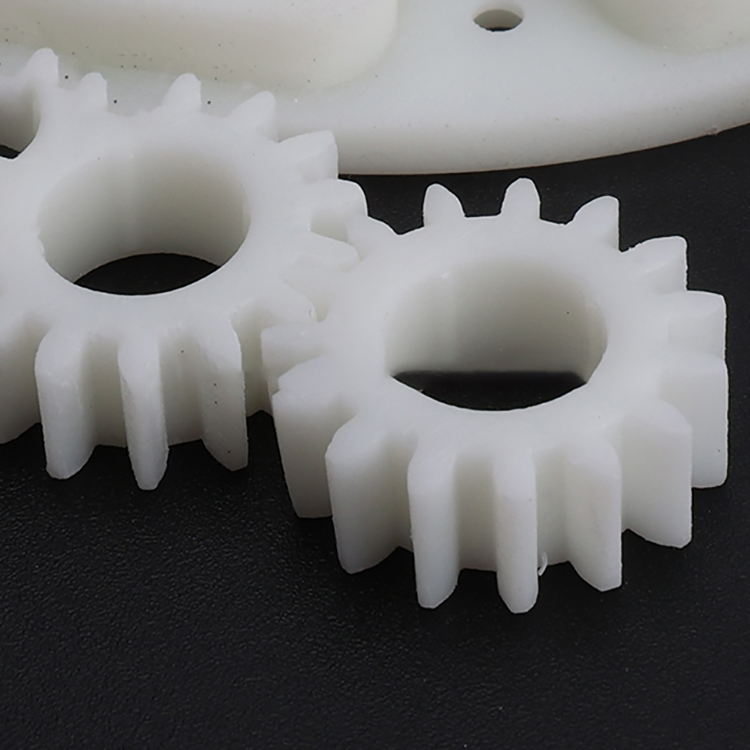

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |