The Importance of Small Plastic Components in Manufacturing

Small plastic components play a crucial role in the manufacturing industry. These tiny parts may seem insignificant, but they are essential for the smooth functioning of various products. From electronics to automobiles, small plastic components are used in a wide range of applications.

One of the primary reasons why small plastic components are so important is their versatility. These components can be molded into various shapes and sizes, making them suitable for different purposes. Whether it’s a tiny gear in a watch or a connector in an electronic device, small plastic components can be customized to meet specific requirements.

In addition to their versatility, small plastic components also offer several advantages over other materials. One of the most significant advantages is their lightweight nature. Plastic is much lighter than metals, making it an ideal choice for applications where weight is a concern. For example, in the automotive industry, small plastic components are used to reduce the overall weight of vehicles, improving fuel efficiency.

Another advantage of small plastic components is their durability. Plastic is known for its strength and resistance to wear and tear. Unlike metals, plastic components are not prone to rust or corrosion, making them suitable for use in various environments. This durability ensures that products incorporating small plastic components have a longer lifespan, reducing the need for frequent replacements.

Furthermore, small plastic components are cost-effective. Plastic is a relatively inexpensive material compared to metals, making it a preferred choice for manufacturers. The low cost of plastic components allows manufacturers to produce products at a lower cost, making them more affordable for consumers. This affordability has contributed to the widespread use of small plastic components in various industries.

Small plastic components also offer design flexibility. Manufacturers can easily mold plastic into complex shapes and intricate designs, allowing for innovative product designs. This flexibility in design opens up new possibilities for product development and enhances the overall aesthetics of the final product.

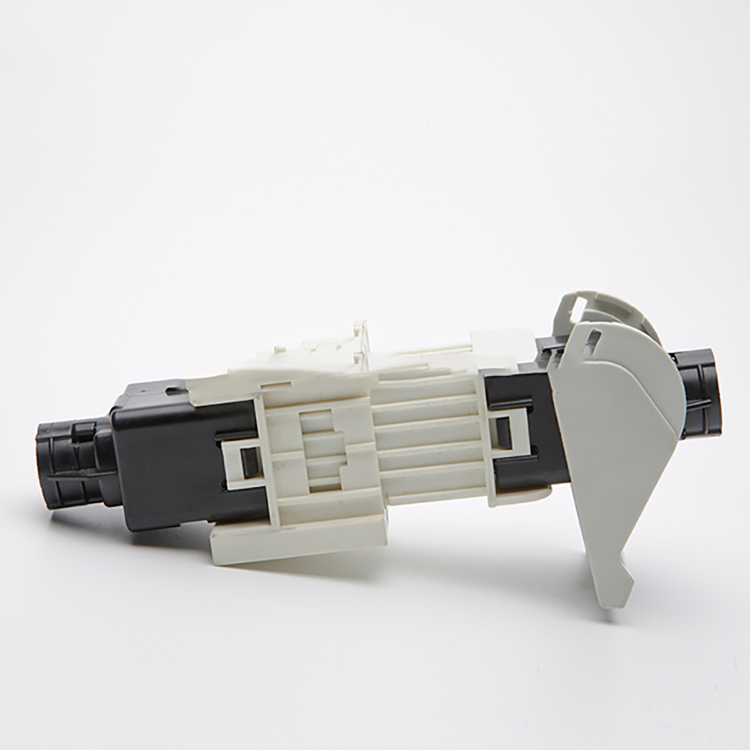

| Product Name | OEM Plastic injection molding Parts |

| Technology | Foaming / Ordinary Injection / Structual Foam Molding / Over-Molding / Gas Assisted Injection Molding |

| Our Services | OEM/ODM |

Moreover, small plastic components are easy to manufacture in large quantities. Plastic injection molding, a common manufacturing process for plastic components, allows for high-volume production with minimal effort. This scalability makes it possible to meet the demands of mass production, ensuring a steady supply of small plastic components for various industries.

Despite their small size, these components play a significant role in ensuring the functionality and reliability of products. They are often the unsung heroes that keep things running smoothly behind the scenes. Without small plastic components, many products would not be able to function as intended.

In conclusion, small plastic components are vital in the manufacturing industry. Their versatility, lightweight nature, durability, cost-effectiveness, design flexibility, and ease of mass production make them indispensable for various applications. From electronics to automobiles, small plastic components are the backbone of many products. So, the next time you use a device or drive a car, remember the importance of these tiny yet essential components.