Introduction to Three Part Plastic Mold

A three-part plastic mold is a type of mold used in the plastic injection molding process. It is designed to create complex plastic parts that cannot be easily produced with a two-part mold. This article will provide an introduction to three-part plastic molds, explaining their purpose, construction, and advantages.

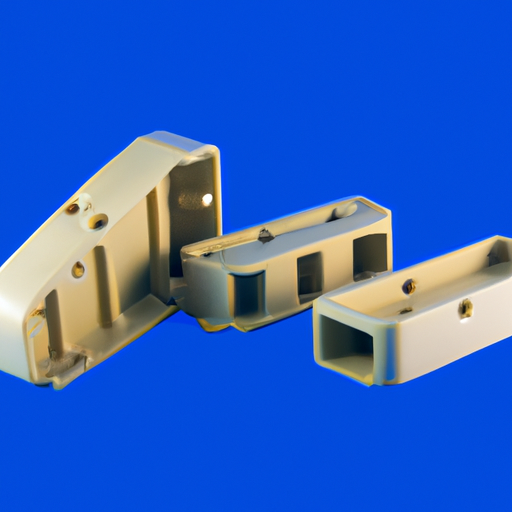

Firstly, let’s discuss the purpose of a three-part plastic mold. This type of mold is used when a plastic part has undercuts or features that prevent it from being easily ejected from a two-part mold. By using a three-part mold, these complex parts can be produced with ease. The three-part mold allows for the creation of intricate shapes and designs that would otherwise be impossible to achieve.

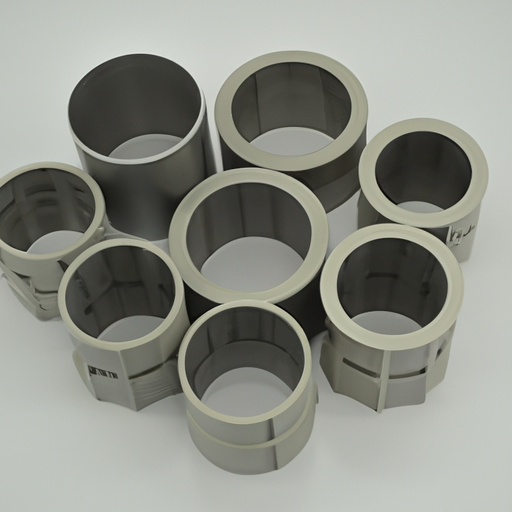

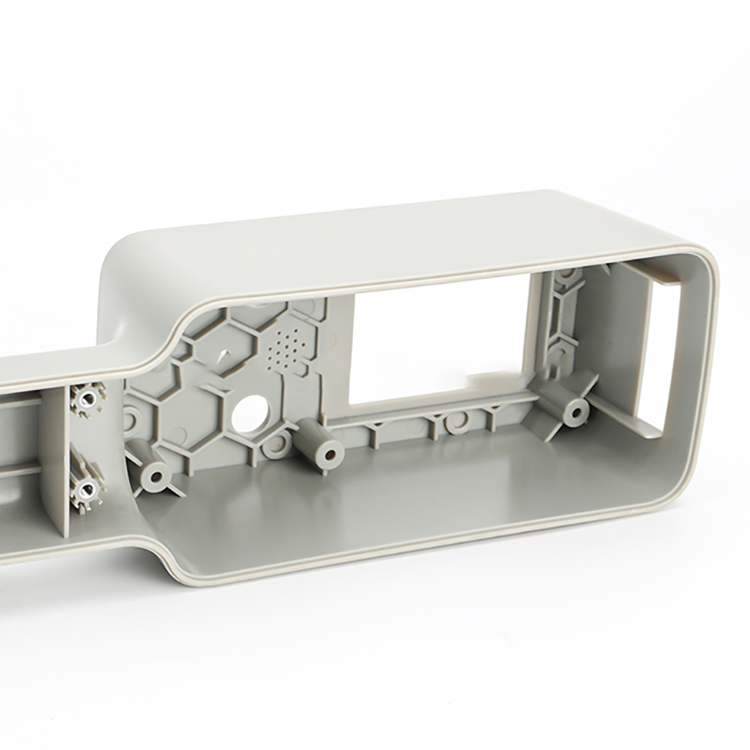

Now, let’s delve into the construction of a three-part plastic mold. As the name suggests, this mold consists of three parts: the core, the cavity, and the ejection system. The core and cavity are responsible for shaping the plastic part, while the ejection system helps in removing the part from the mold once it has solidified. The core and cavity are precision-machined to create the desired shape and texture of the part. The ejection system typically includes ejector pins or sleeves that push the part out of the mold.

One of the advantages of using a three-part plastic mold is the ability to create complex parts with multiple undercuts. Undercuts are features in a part that prevent it from being easily ejected from a mold. With a three-part mold, these undercuts can be accommodated, allowing for the production of intricate designs. This is particularly useful in industries such as automotive, aerospace, and medical, where complex parts are often required.

Another advantage of a three-part plastic mold is the ability to produce parts with different materials or colors. By using multiple cavities within the mold, different materials or colors can be injected simultaneously, resulting in a multi-material or multi-color part. This is especially beneficial in industries where aesthetics or functionality require the use of different materials or colors in a single part.

Furthermore, a three-part plastic mold offers flexibility in the design and production process. The mold can be easily modified or adjusted to accommodate design changes or improvements. This allows for quick iterations and reduces the time and cost associated with creating new molds. Additionally, the use of a three-part mold allows for the production of small quantities of parts, making it suitable for prototyping or low-volume production.

In conclusion, a three-part plastic mold is a valuable tool in the plastic injection molding process. It enables the production of complex parts with undercuts, facilitates the use of different materials or colors, and offers flexibility in the design and production process. Its versatility makes it a preferred choice in industries that require intricate designs and customization. By understanding the purpose, construction, and advantages of a three-part plastic mold, manufacturers can make informed decisions about its implementation in their production processes.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |