The Importance of Design Considerations in Plastic Injection Molding Components

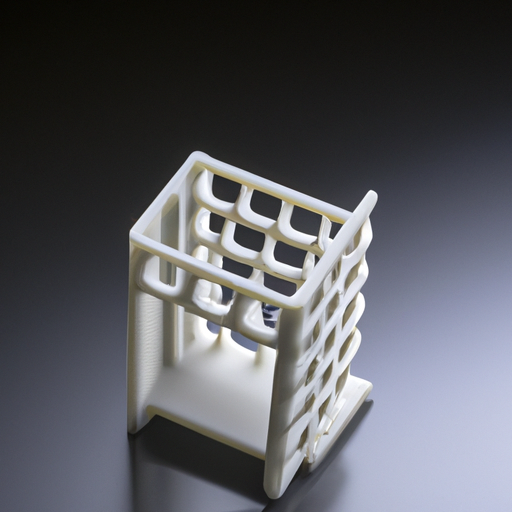

Plastic injection molding is a widely used manufacturing process for producing plastic components. It involves injecting molten plastic into a mold cavity, allowing it to cool and solidify, and then ejecting the finished product. This process is known for its efficiency, cost-effectiveness, and ability to produce complex shapes with high precision. However, the success of plastic injection molding components heavily relies on careful design considerations.

| Product Name | OEM Plastic injection molding Parts |

| Drawing Formats | 2D(PDF/CAD) And 3D(STP/STEP) |

| Materials | ABS / PC+ABS / PC / PP / Nylon (PA6/66) / POM / PVC / PMMA / TPE / TPU / PC+GF / Etc. |

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

One of the most crucial design considerations in plastic injection molding components is the choice of material. The selection of the right plastic material is essential as it directly affects the performance, durability, and appearance of the final product. Factors such as temperature resistance, chemical resistance, mechanical properties, and cost must be taken into account when choosing the material. For example, if the component will be exposed to high temperatures, a heat-resistant plastic should be used to prevent deformation or failure.

Another important design consideration is the wall thickness of the component. The wall thickness affects the strength, rigidity, and overall quality of the part. It is crucial to maintain a uniform wall thickness throughout the component to prevent defects such as warping, sink marks, or voids. Additionally, the wall thickness should be optimized to minimize material usage and reduce production costs. However, it is important to avoid making the walls too thin, as this can lead to weak spots or even breakage.

The design of the mold itself is also a critical consideration in plastic injection molding components. The mold must be designed to accommodate the desired shape and features of the component, as well as to facilitate the injection and ejection processes. The mold design should include features such as draft angles, ribs, and fillets to ensure easy release of the part from the mold and to prevent defects like underfill or flash. Additionally, the mold should be designed for efficient cooling to ensure proper solidification of the plastic and to minimize cycle time.

Furthermore, the design of plastic injection molding components should take into account the presence of inserts or overmolding requirements. Inserts are often used to reinforce or add functionality to the component. They can be made of metal, plastic, or other materials and are placed in the mold before the injection process. Overmolding, on the other hand, involves molding one material over another to create a composite part. Both inserts and overmolding require careful design considerations to ensure proper adhesion, alignment, and functionality.

Lastly, the design of plastic injection molding components should consider the ease of assembly and compatibility with other parts or systems. Components that are difficult to assemble or do not fit well with other parts can lead to production delays, increased costs, and poor product performance. Therefore, features such as snap fits, interlocking mechanisms, or alignment guides should be incorporated into the design to facilitate assembly and ensure proper integration with other components.

In conclusion, design considerations play a crucial role in the success of plastic injection molding components. The choice of material, wall thickness, mold design, inserts or overmolding requirements, and ease of assembly all contribute to the overall quality, functionality, and cost-effectiveness of the final product. By carefully considering these design factors, manufacturers can optimize the performance and durability of plastic injection molding components, leading to satisfied customers and successful products.