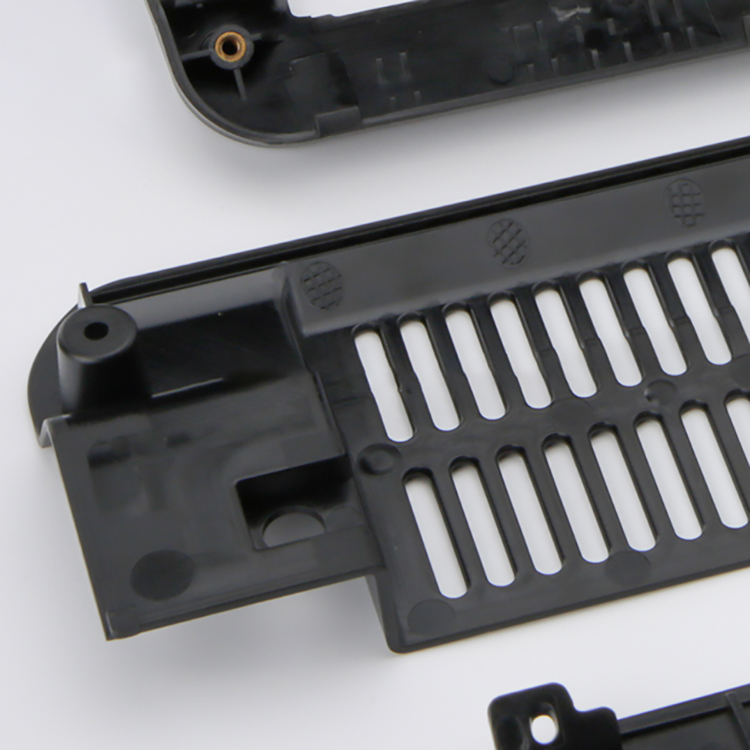

The Advantages of CNC Machining for Plastic PI Components Parts

CNC machining has revolutionized the manufacturing industry, offering precise and efficient production of various components and parts. When it comes to plastic PI components parts, CNC machining proves to be an excellent choice, providing numerous advantages that make it the preferred method for many manufacturers.

One of the key advantages of CNC machining for plastic PI components parts is its ability to produce highly accurate and precise parts. CNC machines are equipped with advanced computer software that allows for precise control and measurement, ensuring that each part is manufactured to the exact specifications. This level of accuracy is crucial for plastic PI components parts, as even the slightest deviation can affect their functionality and performance.

Moreover, CNC machining offers exceptional repeatability, meaning that the same part can be reproduced consistently and accurately. This is particularly important for plastic PI components parts, as they are often used in complex systems where interchangeability is essential. With CNC machining, manufacturers can ensure that each part is identical, eliminating any compatibility issues and streamlining the assembly process.

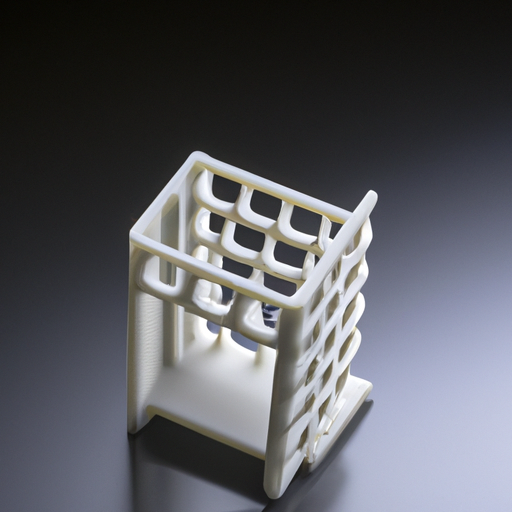

Another advantage of CNC machining for plastic PI components parts is its versatility. CNC machines can work with a wide range of plastic materials, including but not limited to polyethylene, polypropylene, polycarbonate, and acrylic. This versatility allows manufacturers to choose the most suitable material for their specific application, considering factors such as strength, durability, and chemical resistance.

| Production Process | Orders-Raw Materials- Production-Quality Inspection -Packaging-Shipment |

| Our Services | OEM/ODM |

Furthermore, CNC machining offers excellent design flexibility. With traditional manufacturing methods, complex shapes and intricate designs can be challenging to produce. However, CNC machines can easily handle complex geometries, allowing for the creation of intricate plastic PI components parts with ease. This opens up a world of possibilities for designers and engineers, enabling them to push the boundaries of what is possible in terms of design and functionality.

In addition to accuracy, repeatability, versatility, and design flexibility, CNC machining also offers fast turnaround times. Once the design is finalized and the machine is set up, the production process can be carried out quickly and efficiently. This is particularly advantageous for manufacturers who need to meet tight deadlines or respond to sudden changes in demand. CNC machining allows for rapid production, ensuring that plastic PI components parts can be manufactured and delivered in a timely manner.

Lastly, CNC machining for plastic PI components parts is a cost-effective solution. While the initial investment in CNC machines may be higher compared to traditional manufacturing methods, the long-term benefits outweigh the costs. CNC machines are highly efficient, minimizing material waste and reducing the need for manual labor. Additionally, the accuracy and repeatability of CNC machining eliminate the need for costly rework or repairs, saving both time and money in the production process.

In conclusion, CNC machining offers numerous advantages for the production of plastic PI components parts. Its accuracy, repeatability, versatility, design flexibility, fast turnaround times, and cost-effectiveness make it the preferred method for many manufacturers. With CNC machining, manufacturers can ensure the production of high-quality plastic PI components parts that meet the strictest standards and specifications.