Exploring the Different Types of Plastic Injection Molding Machine Components and Their Uses

Benefits of Using Professional Plastics Pte Ltd for Your Business Professional Plastics Pte Ltd is a leading provider of high-quality plastic products and services for businesses across a wide range of industries. With a strong reputation for excellence and a commitment to customer satisfaction, Professional Plastics Pte Ltd is the go-to choice for businesses looking…

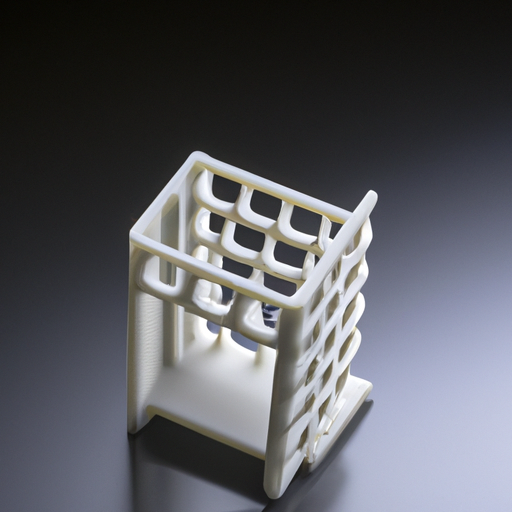

If you’re looking to create a plastic prototype of a functional component, especially for a product or a part that includes a functional aspect such as electronics integration, moving parts, or specific material properties, here are the general steps and considerations involved:Steps to Develop a Plastic Prototype for a Functional Component: 1.Conceptualization and Design: 2.Define…

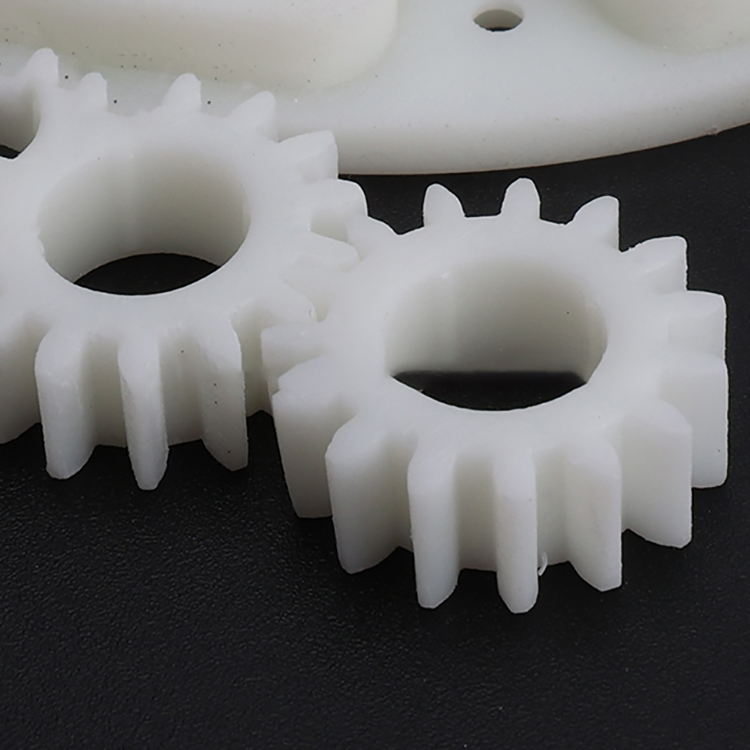

Exploring the Benefits of Plastic Injection Mould Components for Manufacturing Plastic injection mould components are becoming increasingly popular in the manufacturing industry due to their many benefits. These components are used to create a variety of products, from medical devices to automotive parts. Injection moulding is a process that involves injecting molten plastic into a…

The Advantages of CNC Machining for Plastic PI Components Parts CNC machining has revolutionized the manufacturing industry, offering precise and efficient production of various components and parts. When it comes to plastic PI components parts, CNC machining proves to be an excellent choice, providing numerous advantages that make it the preferred method for many manufacturers….

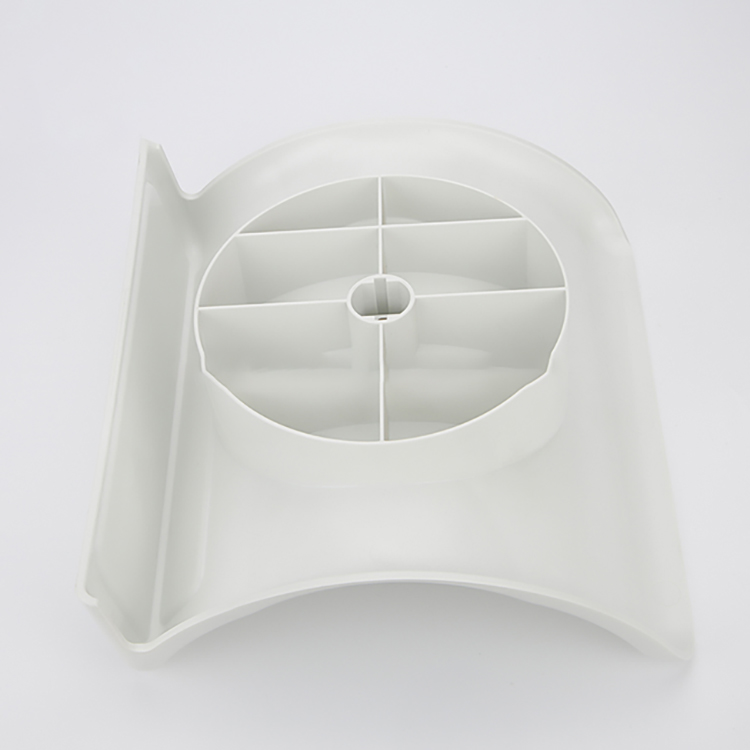

Design Considerations for Plastic Parts: How to Achieve Optimal Performance. Plastic parts are used in a variety of applications, from consumer products to medical devices. While plastic parts offer many advantages, such as cost savings, design flexibility, and lightweight construction, they also come with their own set of design considerations. This blog post will discuss…

Producing ABS injection molded plastic parts for low-volume production involves several considerations and steps to ensure quality and cost-effectiveness. Here’s a structured approach: (1).Design Preparation: Start with detailed CAD designs optimized for injection molding. Ensure designs consider draft angles, wall thickness, and part geometry suitable for ABS.(2).Prototype Development: Create prototypes using rapid prototyping methods like…